COVNA Series Ball Valve – Manually/Electrically/Pneumatically Operated

Ball valves are currently the most widely used and most common type of valve in the valve industry. There is a ball part in the ball valve for opening and closing, which uses the valve stem to drive the ball to rotate 90 degrees, thereby achieving the purpose of opening and closing. The ball valve is mainly used for cutting off, diverting, changing the direction of fluid flow and adjusting the flow rate in the pipeline.

Ball valves are currently the most widely used and most common type of valve in the valve industry. There is a ball part in the ball valve for opening and closing, which uses the valve stem to drive the ball to rotate 90 degrees, thereby achieving the purpose of opening and closing. The ball valve is mainly used for cutting off, diverting, changing the direction of fluid flow and adjusting the flow rate in the pipeline.

● The ball valve has a simple structure. Easy to maintain. Good sealing performance. And it is not easy to leak

● High pressure or high-temperature styles can be customized for special heavy industry

● The ball valve can be made into different connection modes, which is suitable for all kinds of pipelines

● Suitable for wastewater treatment industry, food processing industry, chemical industry, power plant, agriculture, paper industry, etc.

What Are The Types Of Ball Valves?

Ball valves can be divided into different types according to design, function, and material. In order to help you understand and choose COVNA valves you need, the following are the types of ball valves we have.

Ball Valves Types By Materials

.jpg) Stainless Steel Ball Valves

Stainless Steel Ball Valves

The stainless steel ball valve has excellent corrosion resistance and durability performance and it is a valve that can be used in various industries. It can be customized into corrosion-resistant type, high-temperature type, high-pressure type, or low-temperature type, low-pressure type for these special heavy industries.Due to its simple structure, easy maintenance, and high material strength, the stainless steel ball valve can be used in different working conditions and ensure zero leakage.

Carbon Steel Ball Valve

Carbon Steel Ball Valve

Carbon steel ball valves can be processed into different types by using two different processes: forging and casting. They are forged steel ball valves and cast steel ball valves.The forged steel ball valve is produced by forging and can withstand high pressure. Cast steel ball valves are produced by casting technology and are generally used in ordinary working conditions.

Ball Valves Types By Functions

The function of the ball valve is to cut off, divert, change the direction of fluid flow and adjust the flow rate. According to the different functions, it can be divided into:

Shut-Off Ball Valve

All ball valves have a shut-off function. When the ball rotates 90 degrees around the valve stem, it also performs the function of medium circulation or cut-off.

3-Way Ball Valve

The three-way ball valve can be divided into T-type or L-type flow mode, which can achieve the purpose of splitting and changing the fluid flow mode. It provides a high-quality solution for complex flow control.

V-Port Ball Valve

V-Port Ball Valve

The V-shaped ball valve has a V-shaped ball, which can be made into a 30-degree, 60-degree or 90-degree opening, so as to meet your different needs for adjusting the flow ra te. Secondly, the V-shaped ball valve can effectively reduce vibration and noise.

Ball Valve Types By Design

Trunnion Mounted Ball Valves

Trunnion Mounted Ball Valves

Trunnion Mounted Ball Valves means that the ball is fixed in place, which can reduce friction, allow the ball valve to withstand higher pressure, improve the safety and stability of the entire system, well for heavy industries.

Float Ball Valves

Float ball valves mean the ball floating in the valve instead of being fixed in a certain position. Float ball valves are generally used in ordinary applications.

Ball Valves Types By Connections

Threaded Ball Valves

Threaded Ball Valves

The threaded connection is currently the most widely used connection method. Threaded ball valves are generally used on pipes with a size less than 4in. The installation of a threaded ball valve is very simple, but you must also pay attention to comply with the threaded installation standard. Such as G thread standard and NPT thread standard. Secondly, the threaded connection is divided into internal thread and external thread

Flanged Ball Valves

Flanged Ball Valves

Flanged ball valves use nuts and bolts to connect the valve and the pipe. Flanged ball valves can be customized into high-temperature type and high-pressure type, which can be used in different working conditions. Secondly, flanged ball valves are divided into ANSI, JIS, DIN, and GB standards to meet the needs of your country and industry.

Welded Ball Valves

Welded Ball Valves

Welded ball valve means that the ball valve is directly welded to the pipeline, which can play an absolutely leak-proof function. Welded ball valves are generally used in important places to prevent media leakage. Secondly, welding ball valves can be divided into socket welding and butt welding to meet the different needs of your industry.

Ball Valves Types By Assembly

One-piece Ball Valves

One-piece Ball Valves

A one-piece ball valve means that the entire valve body is a whole and cannot be disassembled, meanwhile reducing the possibility of leakage. One-piece ball valve provides an economical valve solution, usually used in normal pressure industries.

Two-Piece Ball Valves

Two-Piece Ball Valves

The two-piece ball valve is the most commonly used valve. Compared with the one-piece ball valve, the two-piece ball valve can be designed into a variety of connections and sizes. Secondly, the two-piece ball valve can be disassembled and repaired.

3-piece Ball Valves

3-piece Ball Valves

The three-piece ball valve can provide the most cost-effective valve solution for complex pipelines and can be customized into low-temperature types, high-temperature types or high-pressure types for different working conditions. The most significant advantage of the three-piece ball valve is that it can be easily and quickly disassembled and repaired, which improves the service life.

Ball Valves Types By Actuation

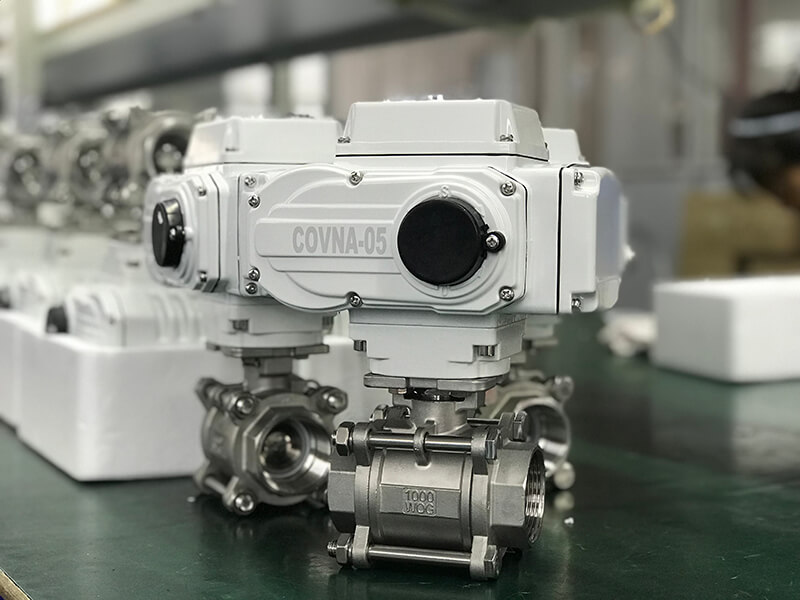

Electric Actuator valve(Motorized Ball Valve)

Electric Actuator valve(Motorized Ball Valve)

Electric ball valve is a kind of valve that opens or closes through AC/DC electricity or signal reception/feedback. It can be remotely controlled and provides a safe and reliable working environment for engineering operators.COVNA series electric ball valves are usually made of stainless steel and plastic material and can be 2-way electric ball valves or 3-way electric ball valves according to the flow mode. According to the application industry, it can be divided into a high-pressure electric ball valve, low-pressure electric ball valve, and normal pressure electric ball valveThe advantage of the electric ball valve is that it can write programs, realize remote control, improve work efficiency and reduce labor costs.

Pneumatic ball valve(Pneumatically Operated Ball Valve)

Pneumatic ball valve(Pneumatically Operated Ball Valve)

The pneumatic ball valve is equipped with a pneumatic actuator, which uses compressed air to drive gear or spring to open and close the valve body.Pneumatic ball valves are divided into single-acting and double-acting types. The single-acting pneumatic ball valve is safe and reliable. There is a spring inside. When the air source is interrupted, the spring drives the valve body to automatically reset. The double-acting pneumatic ball valve runs fast but costs less.Since the pneumatic ball valve is not electrified, its safety performance is very high, and it is not flammable and not explosive.

Manual ball valve(Manually Operated Ball Valve)

Manual ball valve(Manually Operated Ball Valve)

The manual ball valve uses a lever or a turbine to open or close the valve. It is usually made of stainless steel, carbon steel, plastic or brass. The advantages of manual ball valves are low cost and long life.

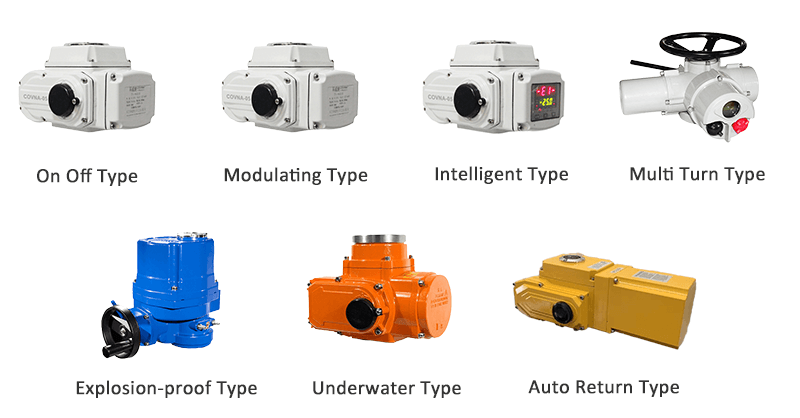

COVNA Industrial Electric Rotary Actuators

● On-off type electric valve actuators: For 90 degrees fully open and fully close. Feedback signal: 4-20mA

● Modulating type electric valve actuators: For regulating the valve angle from 0 degrees to 90 degrees. Feedback and receive signals: 4-20mA, 0-10V or 1-5V

● Intelligent type electric valve actuators: As same as the modulating type actuator. But it has an LCD display screen to help you to check and control easier

● Multi-turn electric valve actuators: 360 degrees rotation for gate valves or globe valves

● Explosion-proof electric valve actuators: NEMA4 or NEMA6 protection class

● Underwater electric valve actuators: IP68 protection class

● Auto return electric valve actuators: Available in fail open or fail close

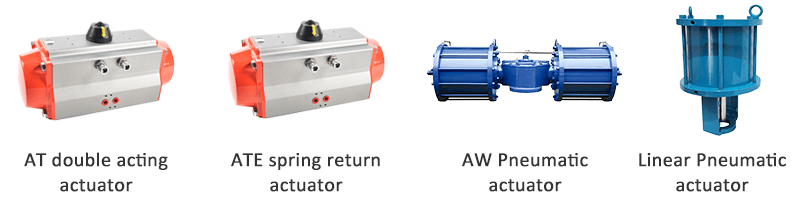

COVNA Pneumatic Rotary Actuator

● AT double acting pneumatic valve actuators: Quarter turn actuators. Supply air to open, supply air to close.

● ATE single-acting pneumatic valve actuators: Quarter turn actuators. Supply air to open, once the air is interrupted, the valve will auto return

● AW pneumatic valve actuators: Available in spring return type and double acting type. Suitable for the ball valve or butterfly valve which has high torque needs

● Linear pneumatic valve actuators: Suitable for gate valves and globe valves

.jpg) Stainless Steel Ball Valves

Stainless Steel Ball Valves Carbon Steel Ball Valve

Carbon Steel Ball Valve

V-Port Ball Valve

V-Port Ball Valve

_1.jpg)

Two-Piece Ball Valves

Two-Piece Ball Valves 3-piece Ball Valves

3-piece Ball Valves