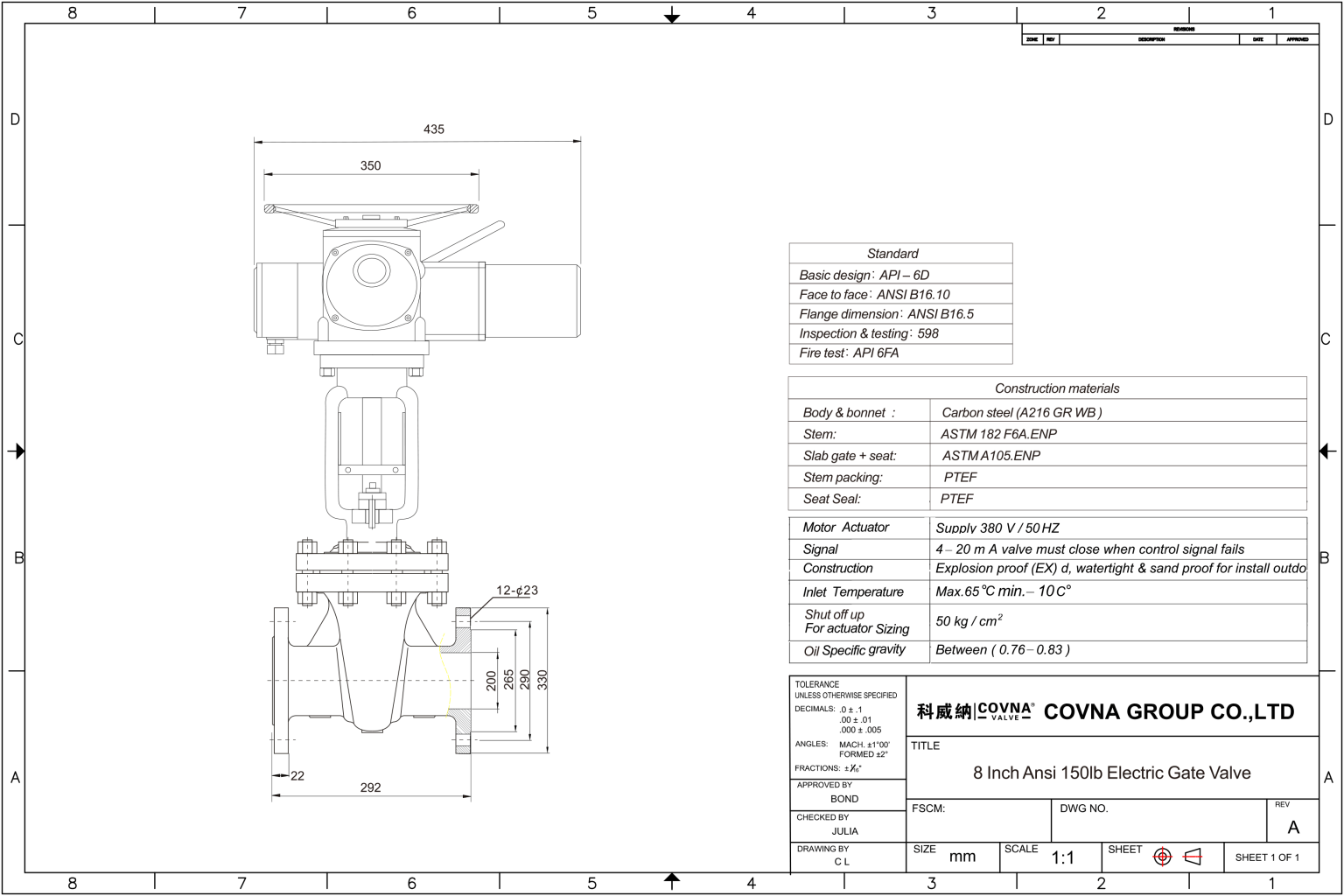

Cast Iron Multi Turn Electric Actuator Gate Valve

Electric Actuated Wedge Gate Valve

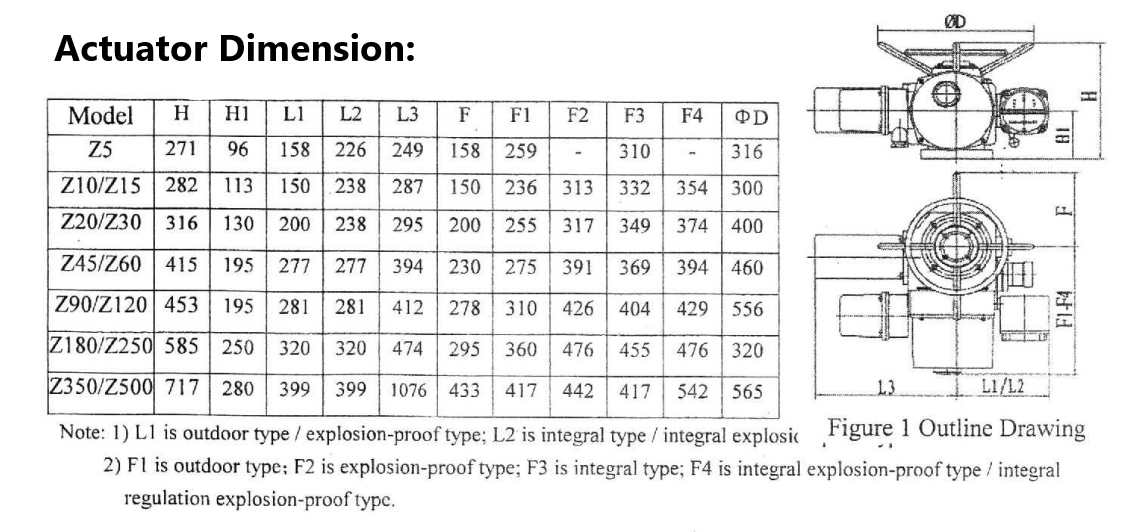

This product is appropriate for a variety of industries: power, metallurgy, petrochemical, paper, and waste treatment. Its multi-turn electric actuator can be classified into different types based on the operational setting and functional specification requirements: outdoor type for outdoor works, explosion-proof type satisfying explosion-proof requirements, highly integrated type, and adjustable integral type with adjustment capability. Composite products are also extended to wholly controllable explosion-proof types and wholly adjustable explosion-proof types. Furthermore, the actuator can be divided based on valve connection methods into two thrust categories, nuanced by motion: torque type controlled by rotational force and thrust type governed by axial thrust. These distinctions allow tailored actuation solutions responsive to varied operational conditions.

Technical Parameters of Valve Actuator

| Power supply | general: single-phase 220v, three-phase 380v(50Hz), long distance DC24V |

| special: single-phase 110v, three-phase 415v, 660v(50Hz, 60Hz) | |

| Working environment |

Ambient temperature: -20 ~ + 60 ℃ (special temperature environment can be customized) |

| Relative humidity: 95% (at 25 ° C) | |

| The outdoor type can be used in the places without inflammable / explosive and corrosive medium | |

| d I | applicable to non-excavating workinarea for coal mine |

| d I BT4 | applicable to the environment with IIA , IIB grade TL-T4explosive gas mixture , can be used in the factory |

| Protection level | Outdoor type and explosion-proof type are IP55 (IP65, IP67) |

| Working time | short time 10 minutes (15-60 minutes for special order) |

Technical Parameters of Valve Body

Technical Parameters of Valve Body

| Valve Body | Valve components | ||

| Nominal size | DN50-DN400 | Sealing material | PTFE, EPDM |

| Body Material | Stainless Steel | Disc Material | Stainless Steel |

| End Connection | Flange Ends & Butt welding Ends | Stem Material | Carbon iron |

| Operating Pressure | ASME CL, 150, 300, 600, 900, 1500, 2500 | Applicable media | Water, Air, Gas, Petroleum, Oil, Liquid |