HK60-D-F Flanged Motorized Butterfly Valve

What Is Motorized Butterfly Valve

Motorized butterfly valve is a control valve widely used in various industrial fields. It consists of a metal "butterfly" that can rotate and completely or partially close the valve inside a pipeline, thus controlling the flow and pressure of fluid. Motorized butterfly valve usually consists of components such as a disc, valve stem, transmission components, electric motor, position indicator, and controller.

Its benefits include space saving, ease of maintenance, wide application and automation capabilities, making it an efficient, accurate and reliable control valve and is used in a wide range of industries such as the chemical industry, oil and gas, pharmaceuticals, food processing, water treatment and many more.

Benefits Of Electric Flanged Butterfly Valves:

COVNA Electric Flanged Butterfly Valves provide a reliable and efficient fluid control solution for you. Flanged butterfly valve can be customized to ANSI standard, JIS standard, DIN standard or GB standard according to your pipeline requirements. Moreover, the parts of the butterfly valve can be replaced according to your project requirements, including valve plate, seal, valve body materials, etc., to meet your high pressure, high temperature or anti-corrosion needs.

It can be used with electric actuators to easily realize remote control and realize industrial automation.

Features Of HK60-D-F Flanged Motorized Butterfly Valve(Motorized Ducting Butterfly Valve):

● 5 sealing options: NBR, EPDM, VITON, PTFE and Metal

● Flanged connection with features of easy to install

● On/Off type, regulator type and intelligent type electric actuator available to help you control the valve locally or remotely easier

● Widely used in FGD industry, air ducting, wastewater treatment, power plant, shipyard, paper and pulp, food and beverage, etc

● Available in soft-sealing and hard sealing for your different requirements

Soft Sealing Type

Available in EPDM and PTFE sealing for your choice

Hard Sealing Type

Metal hard sealing for special applications

Technical Parameters Of HK60-D-F Flanged Motorized Butterfly Valve:

| Medium | Air, water, oil, gas, steam, etc | Port size | 2", 2.5", 3", 4", 5", 6", 8", 10", 12", 14", 16", 18", 20", 22", 24". Up to 72" |

| Structure | Double offset type or Triple offset type | Voltage | DC-12V, 24V; AC-24V, 110V, 220V, 380V |

| Connection Type | Flanged (ANSI, JIS, DIN, GB) | Voltage Tolerance | ±10% |

| Body Materials | Cast iron, Stainless steel 304/316/316L or WCB | Working Pressure | Soft Seated:16 bar ;

Hard Seated: 40 bar |

| Disc Material | Stainless steel 304/316/316L | Temperature Of Media | Soft Seated: -10℃ to 180℃ ; Hard Seated:-40℃ to 450℃ |

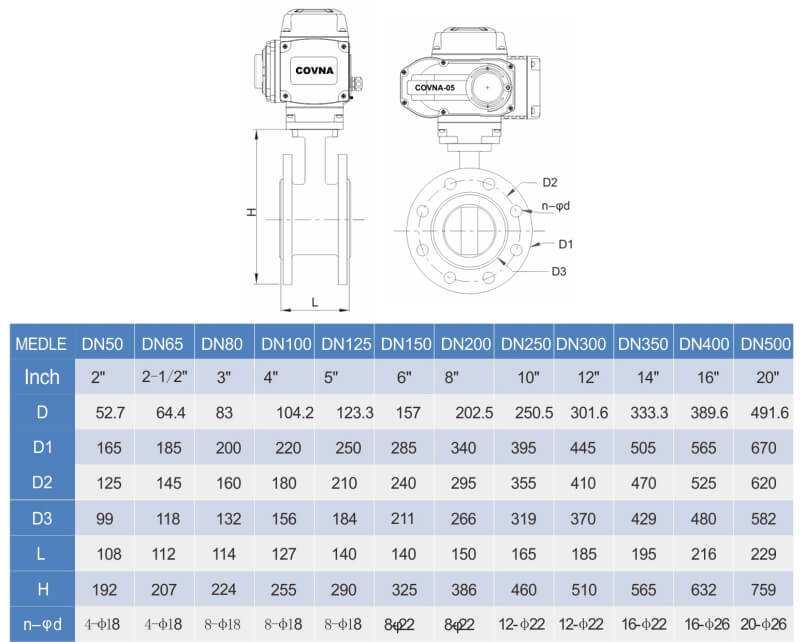

Dimension Of HK60-D-F Flanged Motorized Butterfly Valve:

Technical Parameters Of COVNA Quarter Turn Electric Actuators:

| ON/OFF Type | Feedback: the active contact signal, passive contact signal, resistance, 4-20mAFor 90 degrees open or close fully |

| Regulator Type | Input & Output signal: DC 4-20mA, DC 0-10V, DC 1-5VFor regulating the open/close angle of the valve from 0 to 90 degrees. |

| Field Operation | The field, remote control switch regulation and MODBUS, PROFIBUS field bus |

| Voltage optional | AC 110-240V 380V 50/60Hz; DC12V, DC24V, Special voltage can be customized |

| Protection Class | IP65 |

| Options | Manual override, Bluetooth control or LCD display screen |

| Model | 5 | 10 | 16 | 30 | 60 | 125 | 250 | 400 |

| Torque Output | 50Nm | 100Nm | 160Nm | 300Nm | 600Nm | 1250Nm | 2500Nm | 4000Nm |

| 90°Cycle Time | 20s/60s | 15s/30s/60s | 30s/60s | 100s | 100s | 100s | ||

| Angle of Rotation | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° |

| Working Current | 0.25A | 0.48A | 0.68A | 0.8A | 1.2A | 2A | 2A | 2.7A |

| Starting Current | 0.25A | 0.48A | 0.72A | 0.86A | 1.38A | 2.3A | 2.3A | 3A |

| Drive Motor | 10W/F | 25W/F | 30W/F | 40W/F | 90W/F | 100W/F | 120W/F | 140W/F |

| Product Weight | 3kg | 5kg | 5.5kg | 8kg | 8.5kg | 15kg | 15.5kg | 16kg |

| Voltage Option | AC 110V, AC 220V, AC 380V, DC 12V, DC 24V | |||||||

| Insulation Resistance | DC24V:100MΩ/250V; AC110/220V/380V: 100MΩ/500V | |||||||

| Withstand Voltage | DC24V:500V; AC110/220V:1500V; AC380V:1800V 1Minute | |||||||

| Protection Class | IP65 | |||||||

| Installation Angle | Any | |||||||

| Electrical Connection | G1/2 Water-proof Gable Connectors, Electric Power Wire, Signal Wire | |||||||

| Ambient Temp. | -30℃to 60℃ | |||||||

| Control Circuit | A: ON/OFF type with light indicator signal feedback | |||||||

| B: ON/OFF type with passive contact signal feedback | ||||||||

| C: ON/OFF type with resistance potentiometer signal feedback | ||||||||

| D: ON/OFF type with resistance potentiometer and neutral position signal feedback | ||||||||

| E: Regulation type with a servo control module | ||||||||

| F: DC24V/DC12V direct ON/OFF type | ||||||||

| G: AC380V three-phase power supply with passive signal feedback | ||||||||

| H: AC380V three-phase power supply with resistance potentiometer signal feedback | ||||||||

| Optional Function | Over Torque protectors, dehumidify heater, stainless steel coupling & yoke | |||||||

Other COVNA Electric Actuator Options:

● Explosion-proof Electric Actuator: Exd II CT4 protection class to keep your project and personal safe. Torque range from 100Nm to 2,000Nm

● Auto Return Electric Actuator: In the event of a power failure, the battery drives the valve to reset. Suitable for use in the fire protection industry. Torque range from 100Nm to 6,000Nm

● Waterproof Electric Actuator: IP68 protection class and suitable use underwater. Like subsea exploration projects. Torque range from 50Nm to 2,000Nm