HK60ZS Motor Operated Gate Valve

What Is Motor Operated Gate Valve?

Motor operated gate valve is a type of valve that uses an electric motor to control the flow of liquid or gas. It's often used in factories or plants where they need to precisely control how much fluid goes through pipes.

The valve works by having a flat or curved gate that opens and closes inside the valve body, controlling the flow of fluid. The electric motor is connected to the gate and can open or close it with precision. This is helpful because it allows the valve to be controlled from a distance and can avoid safety risks for workers who need to control the flow of fluids in large pipes.

Motor operated gate valves are known for their reliability and durability, and they can be customized to fit specific applications. They're often used in large pipeline systems where it would be impractical or dangerous for an operator to manually open or close the valve. By using an electric motor instead, the valve can be controlled remotely and with greater precision.

Features Of HK60ZS Motor Operated Gate Valve:

● The flow resistance is small, the sealing surface is not easy to be eroded and corroded by the medium, and the service life is long

● Unrestricted medium flow direction, simple installation

● Large size range for choice and it can be applied to all kinds of pipelines

● Small switching torque, easy to control

COVNA Motor operated gate valve is suitable for a wide range of industries because it uses materials commonly found in local industry, such as CF8, CF8M, WCB, and more.

CF8 steel is strong against corrosion and wear, making it popular in chemical, food processing, and pharmaceuticals.

CF8M steel is even more resistant to corrosion, perfect for marine engineering, seawater treatment, and petroleum industries.

WCB steel has excellent weldability and is often used in low-pressure pipelines in oil and gas, as well as power industries.

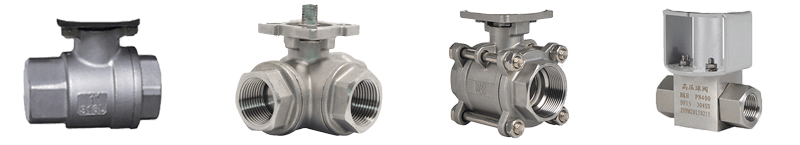

Types Of Motor Operated Gate Valve For Your Choice:

Technical Parameters Of Gate Valve:

| Size range | 1/2in to 28in |

| Pressure range | 10bar / 16bar /25bar / 40bar /64bar |

| Medium temperature | -40℃ to 450℃ |

| Material Options | WCB, CF8, CF8M |

| Connection | Flange |

| Connection Standard | ANSI, JIS, DIN, GB |

| Mediums | Water, wastewater, pulp, steam, oil |

| Gate Valve Body Design Standard | API600 / DIN3352 / KS B2361 / GB/T 12234 |

Technical Parameters Of Multi-turn Electric Actuator:

| Torque Range | 50Nm to 10,000Nm |

| Rotation | 360 degree |

| Working Voltage | Conventional: Three-phase: AC380VSpecial: Three-phase: AC660V, AC440V, AC415VSpecial: Simplex: AC220V, AC110VSpecial: Direct: DC12V, DC24V, DC48V |

| Ambient Temperature | -30℃ to 70℃ |

| Environment Humidity | ≤95% |

| Input Signal | 4~20mA |

| Protection Class | IP65/IP68 |

| Explosion-proof Class | ExdII BT4, Exd II CT4 |

| Control Methods Options | Ordinary type, intelligent switch type, intelligent adjustment type(Profibus Fieldbus, Modbus Fieldbus, HartFieldbus, FFFieldbus, Device NetFieldbus) |

Design and manufacturestandard of ANSI Gate Valve:

| Design and manufacture | API600 ASME B16.34 |

| Face to face | ASME B16.10 |

| End flange dimension | ASME B16.5, ASME B16.47, ASME B16.25 |

| Test | ISO5208 API598 |

Design and manufacturestandard of JIS Gate Valve:

| Design and manufacture | KS B2361 |

| Structure length | KS B2361 |

| Flange size | KS B2361 |

| Test | KS B2361 |

Design and manufacturestandard of GB Gate Valve:

| Design and manufacture | GB/T 12234 |

| Structure length | GB/T 12221 |

| End flange dimension | JB/T 79 |

| Test | JB/T 9092 |

Design and manufacturestandard of DIN Gate Valve:

| Design and manufacture | DIN 3352 |

| Structure length | DIN 3202 |

| End flange dimension | DIN 2543 |

| Test | DIN 3230 |