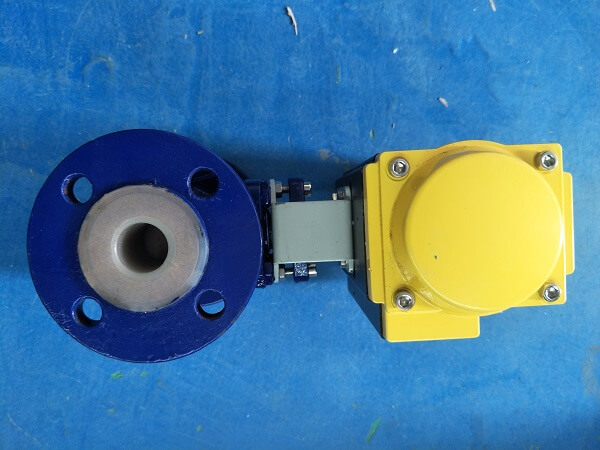

With the continuous application of new chemical materials and the improvement of lining technology, Fluorine-Lined Control valves and cut-off valves are favored by manufacturers and users for their safety and reliability and high cost-performance ratio In the petroleum, chemical industry, medicine and other industries strong corrosion process media are more and more widely used. But lined fluorine valve is not able to adapt to all corrosive working conditions, as with other valves, how to choose and use lined fluorine valve, is a professional work. We will explain from the following four aspects of fluorine-lined valve how to used.

1. Fluorine-Lined Valve Temperature Should Be Lower Than The Upper Limit Of About 30%

Temperature for fluorine-lined Valves: currently the most common seal for fluorine-lined valves is the polytetrafluoroethylene PTEF (- 200-180°c) . The above is open to check the limit of each material temperature, the actual use of media temperature according to the material, pressure and different, long-term, the use of temperature should usually be lower than the upper limit of about 30% , otherwise, the valve parts lining easily deformed, causes the leakage quantity to be big or the valve can not normally switch and so on breakdown.

2. Fluorine-Lined Valves Are Not Suitable For High Pressure And High Differential Pressure Situations

Fluorine-lined Valve pressure (poor) : fluorine-lined valves are usually not used in high vacuum working conditions, when it is really necessary to apply in high vacuum working conditions, corresponding measures should be taken (such as opening dovetail groove in the metal valve body cavity, punching the valve plate, etc.), to prevent the valve inner lining fluorine, lining plastic layer was drawn out (drum bag) , lining layer and metal layer peeling, resulting in the valve cannot open and close normally.

The same lining fluorine valve is not suitable for use in high pressure, high differential pressure situation. Especially for the flouride-lined bellows Seal Control Valve (because the bellows are mostly made of polytetrafluoroethylene, which is easy to cause the bellows to rupture when the pressure and pressure difference are too large) , most manufacturers choose the type sample that the nominal pressure is PN ≤2.5 MPA It’s just a precaution. But sometimes because of the special working condition, also need to find a solution.

3. The Medium Should Not Have Hard Particles, Crystals, Impurities, etc.

Fluorine-lined Valve medium requirements: fluorine-lined (plastic) valve medium should not have hard particles, crystals, impurities, so as to avoid the valve in the open, closed operation of wear and tear lined fluorine-lined plastic layer or bellows. For medium with hard particles, crystal, impurities, according to the characteristics of the process media can choose corrosion-resistant precious metal materials, such as Harrington Alloy, nickel-based alloy, alloy steel and other hard seal valve.

4. Fluorine-Lined Valves Should Be 30-85% In Size

The fluorine-lined regulating valve is usually made into a sealing structure of fluorine-lined bellows, which has the advantages of good corrosion resistance and no leakage. In the selection, should be based on the process parameters to calculate the valve diameter, the normal opening should be in the range of 30 ~ 85%. If the valve size is too large, will cause long-term in the opening of small circumstances, valve regulation performance. In particular, in the case of a small opening, not only scour, but also make the valve core, valve stem by the impact of the media vibration, and even make the valve stem fracture, bellows deformation.

Post time: Jul-28-2021