As a valve manufacturer, COVNA manufactures all kinds of valves for pipelines. Such as gate valve, globe valve, ball valve, butterfly valve, check valve and so on. Available in electrically operated, pneumatically operated and manually operated for your options.

Consult us to get a free valve solution with the best price! sales@covnavalve.com

1. Overview

Pipeline transportation has become the main way of modern energy transportation, using long-distance pipeline to transport oil, gas, coal and other resources has become the most important means of energy transportation in the world. The major oil and gas producing and consuming countries in the world use long-distance pipeline to solve the transportation problem of oil and gas resources, and more than 95% of the natural gas is transported by pipeline. According to statistics, there are more than 2.6 million kilometers of long-distance oil and gas pipelines in the world, of which the total length of natural gas pipelines is about 1.4 million kilometers, accounting for more than half of the total length.

The open-close and control valves should be installed at the starting point, the middle booster station, the trunk line and the inlet and outlet of each system in the long distance pipeline. Long-distance oil and gas pipelines may break, leak oil and gas, catch fire and explode because they may be affected by various disasters and accidents. Also need to set up an emergency shut-off Valve, electric valve or pneumatic valve and other valves.

It can be seen that many valves will be used in a long-distance pipeline.

The long-distance pipeline passes through deserts, swamps, mountains and plains, where the weather is bad and the environment is bad. Therefore, the requirement for valves is higher than that for general valves pipeline valves should have higher strength and better sealing performance, higher service life, quick and convenient operation and maintenance.

Foreign long-distance pipelines have started early and developed rapidly. China does not yet have large-diameter long-distance pipelines. The construction of large-diameter long-distance pipelines is at the initial stage. Therefore, we must do a good job of supporting product standards, product performance inspection and other work.

2. General Situation Of Valves For Long-Distance Pipeline

It is necessary to control the flow of medium in long-distance pipeline transportation, so a large number of valves are needed in the pipeline. Valves on long-distance pipelines are used for 2 main purposes:

(1). In the main line and the entrance and exit of the system, open and close the role and security protection.

(2). In the beginning station and the Middle Booster Station of the pipeline, it plays the role of controlling the transmission of medium.

The most widely used valves in the long-distance pipeline are: flat gate valve, ball valve, emergency cut-off ball valve, check valve, quick ball control valve and so on. The valve is connected in the form of farlane joint and butt weld. Valve drive: manual, electric, pneumatic, hydraulic, electric-hydraulic linkage, gas-hydraulic linkage and other forms of driving.

2.1 From the perspective of the development trend of the valves used in long-distance pipelines, the following characteristics and functions of the valves are required:

(1) Valve with good sealing performance (suitable for various media and variable operating conditions).

(2) Valves with good fire resistance.

(3) Valve with compact structure, small size, corrosion resistance and wear resistance.

(4) Apply to the long-distance pipeline large diameter valves and liquefied natural gas high pressure low temperature valves.

(5) The utility model is convenient for pigging and has good anti-external stress structure.

(6) Mechatronics engineering valves.

2.2 The Structural Features And Functions Of Various Valves For Pipelines

(1) Flat Gate Valve

The main features of the Flat Gate Valve are: shorter structure length, better sealing performance, less operating torque and close opening and closing operating force, small flow resistance, the valve does not need to set an abnormal pressure-raising device, a flat gate valve with a diversion hole may be used to clean the line by means of a sweeper. But the valve structure is high, about 3-4 times the diameter of the pipeline.

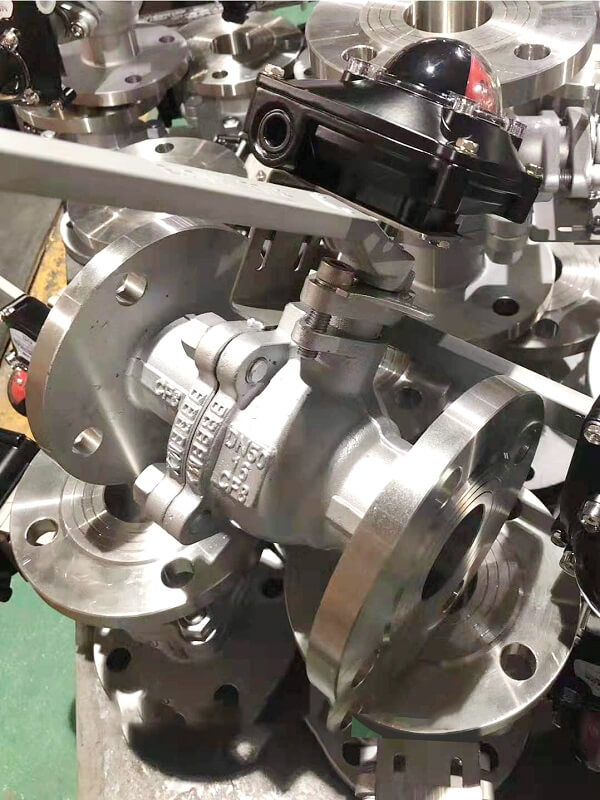

(2) Ball Valve

The main features of the ball valve are: Compact structure, good sealing performance, open and close 90 rotation can quickly open and close the valve, operating time is short, using injection sealant can form a secondary auxiliary seal, the fire-proof structure of the valve seat can ensure the sealing of the valve in case of fire. The quick-cutting device can realize the emergency opening and closing of the valve.

(3) Ball Control Valve

Ball valve flow, simple structure, good stability, easy operation and maintenance, full-open flow resistance, allowing the use of large pressure difference, low noise, good cavitation resistance.

(4) Check Valve

Check Valve with multi-damping structure, can effectively eliminate the vibration of the pipeline and reduce the flow resistance; using double seals (low pressure with elastic seal, high pressure with metal-metal seal) , sealing effect is good; can be through the pipeline sweeper.

(5) Relief Valve

Because start or stop the pump may cause in the pipeline medium velocity changes and pressure fluctuations, resulting in shock waves. In order to eliminate the impact of the shock wave, the pressure relief valve is used to reduce the shock wave on the long-distance pipeline.

(6) Pressure Relief Valve

The pressure reducing valve is set on the branch pipeline, which is used to keep the medium pressure at the user’s inlet. The pilot pressure reducing valve is usually used.

Post time: Jul-28-2021