The way in which a valve is connected to a pipe is called connection. The ball valve has 4 kinds of connection modes, which are screw thread, Flange, clamp and welding. Each connection has its own characteristics and advantages. Different pipes are connected in different ways. In this article, we will share the 4 types of connections and their features to you. Any demand for valve, feel free to consult us at sales@covnavalve.com

1. Threaded Connections

This connection is usually the valve inlet and outlet into the cone pipe thread, screw it into the cone pipe thread joint or pipe. As this connection may appear larger leakage channel, so sealant can be used. Sealing tape or packing to block these channels. If the body material is weldable, the threaded joint can also be sealed for welding. If the material of the connecting parts is allowed to be welded, but the Coefficient of expansion varies greatly, or the range of working temperature is large, the threaded connecting parts must be sealed welding.

The valve with screw thread connection is mainly the valve with nominal diameter below 50mm. If the size of the diameter is too large, it is very difficult to install and seal the connecting part.

To facilitate installation and removal of threaded valves, pipe fittings are available in the appropriate position in the piping system. Valves with nominal sizes below 50 mm may be joined by a sleeve joint whose threads connect the two parts together.

Threaded connection is the most commonly used connection, generally used in solenoid valves, motorized ball valves, pneumatic actuator ball valves, angle seat valves and so on.

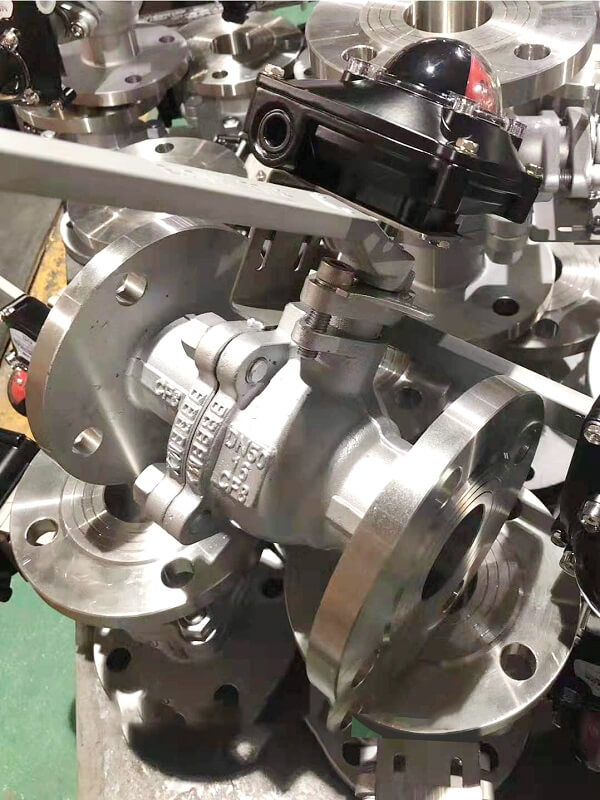

2. Flange Connections

Flanged valves are easy to install and disassemble. But compared to the heavy thread connection, the corresponding price is also higher. The biggest advantage of flange connection is that its size range is very wide, generally 1 / 2 Inch to 8 inches, higher can be customized, so applicable to a variety of sizes and pressures of pipe connection. However, when the temperature exceeds 350 °C, due to the creep relaxation of the screw, gasket and Flange, the load of the screw can be obviously reduced, and leakage may occur in the flange connection which is under great stress.

Flanged connections are widely used for pipes of various sizes. Generally used for flange solenoid valve, flange electric ball valve and so on.

3. Weld Connections

This kind of connection is suitable for all kinds of pressure and temperature, and is more reliable than flanged connection when used under more severe conditions. But welded valves are difficult to disassemble and reinstall, so their use is limited to situations where they can normally be operated reliably over a long period of time, or under harsh operating conditions and high temperatures. Such as fossil-fuel power station, nuclear power projects. On the pipeline of the B & S Project.

Welding valves up to 50 mm in nominal size usually have a weld socket for the flat end of the pipe. Because socket welding is in the gap between the socket and the pipe, it is possible to make the gap be corroded by some medium, and the vibration of the pipe will make the joint fatigue. Therefore, the use of socket welding is limited.

In the case of large nominal diameter, harsh service conditions and high temperature, the valve body is often welded by groove, and the welding seam is strictly required.

4. Tri Clamp Quick Connections

The Quick Assembly connection of the clamp can effectively avoid the contact between the medium and the air and prevent the medium from being polluted. Therefore, the clamp connection mode is suitable for the industrial environment such as food, beverage, chemical industry, medicine, life science, etc. As well as bioengineering, filtration and Water Treatment Technology Industries. For circulation of milk, drink, pure water and other media.

Such as tri clamp food grade motorized ball valve, tri clamp pneumatic ball valve, clamps solenoid valve and so on.

Post time: Jul-28-2021