I am very happy to introduce a new project we recently received to you – the milking system CIP. The milking system CIP consists of 4 steps: warm water rinse, alkaline rinse, acid rinse and disinfection. CIP is an automated process. The valve plays the role of circulation and isolate in this process, assisting the system to complete the pipeline cleaning and disinfection, and ensuring the safety of dairy products.

Below, we will introduce you to the valves that can be used in CIP systems. Hope to help you understand and choose the right valve.

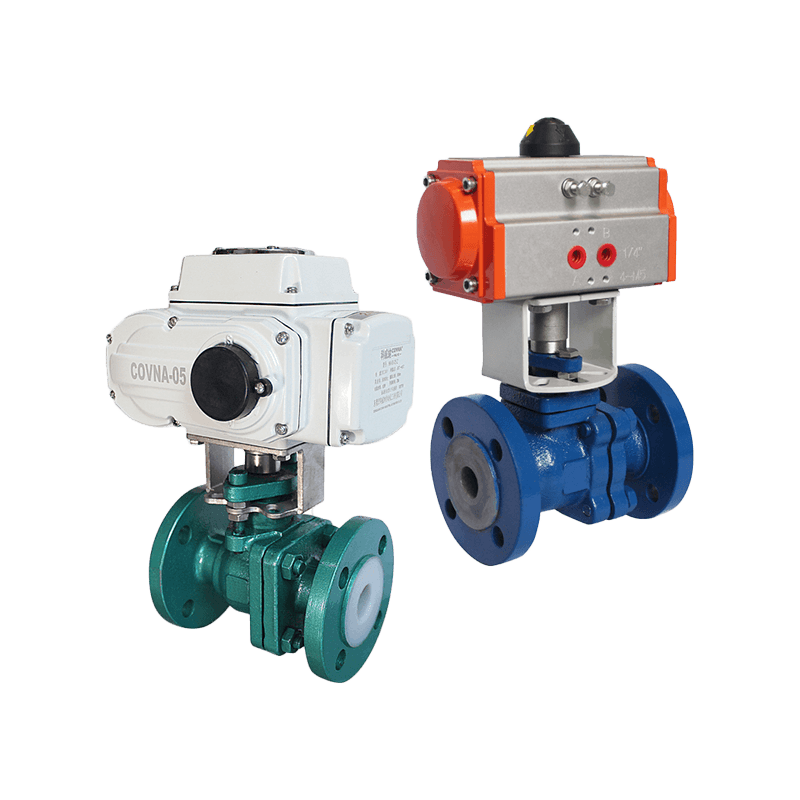

Ball Valve

The ball valve is a quarter-turn valve. We can provide you with a 2-way ball valve or a 3-way ball valve. Helps you circulate, isolate or redirect fluid flow. Furthermore, since the CIP process will contain acids and alkali, corrosion-resistant valves are required. We can supply fluorine lined ball valve to you. The fluorine-lined ball valve adopts PTFE seal and PTFE ball, which has excellent anti-corrosion performance and can be well used for the control of flow rate of acid and alkali.

Can provide manual fluorine lined ball valve, electric fluorine lined ball valve and pneumatic fluorine lined ball valve for your choice.

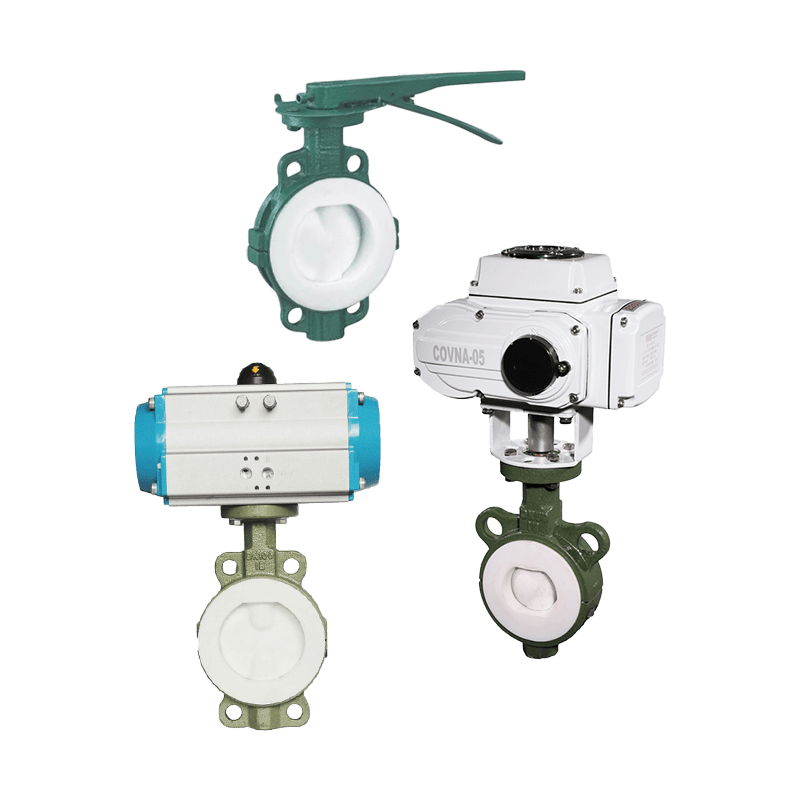

Butterfly Valve

The advantage of butterfly valves is that they have a large size range and can be used in various pipelines to control the flow of fluids. Likewise, we can provide fluorine lined butterfly valves for your use. The fluorine-lined butterfly valve contains PTFE seal and PTFE disc, which has first-class anti-corrosion performance and can control the flow of acid and alkali well.

COVNA can provide manual fluorine lined butterfly valve, electric fluorine lined butterfly valve and pneumatic fluorine lined butterfly valve for your choice.

In addition, we also provide sanitary valves, including sanitary ball valves and sanitary butterfly valves for your choice.

Post time: May-05-2022