The pulping process is a process of preparing, cooking, washing and bleaching raw materials rich in fiber such as wood into pulp that can be made into paper.

In the papermaking process, the pulp sent by the pulping department is subjected to pulping, streaming, pressing, drying, coiling and other processes to produce finished paper. In this process, the pneumatic knife gate valve is often used. The pneumatic knife gate valve can quickly cut off the turbid mud in this process, and it will not be blocked, and the flow rate is large.

For the paper industry, the main media encountered in production are: slurry, steam, water, sewage and black liquor. For steam, the pneumatic control valve is commonly used, which can adjust the flow rate and pressure of the pipeline, and is powered by compressed air, without electricity, and is safe and explosion-proof.

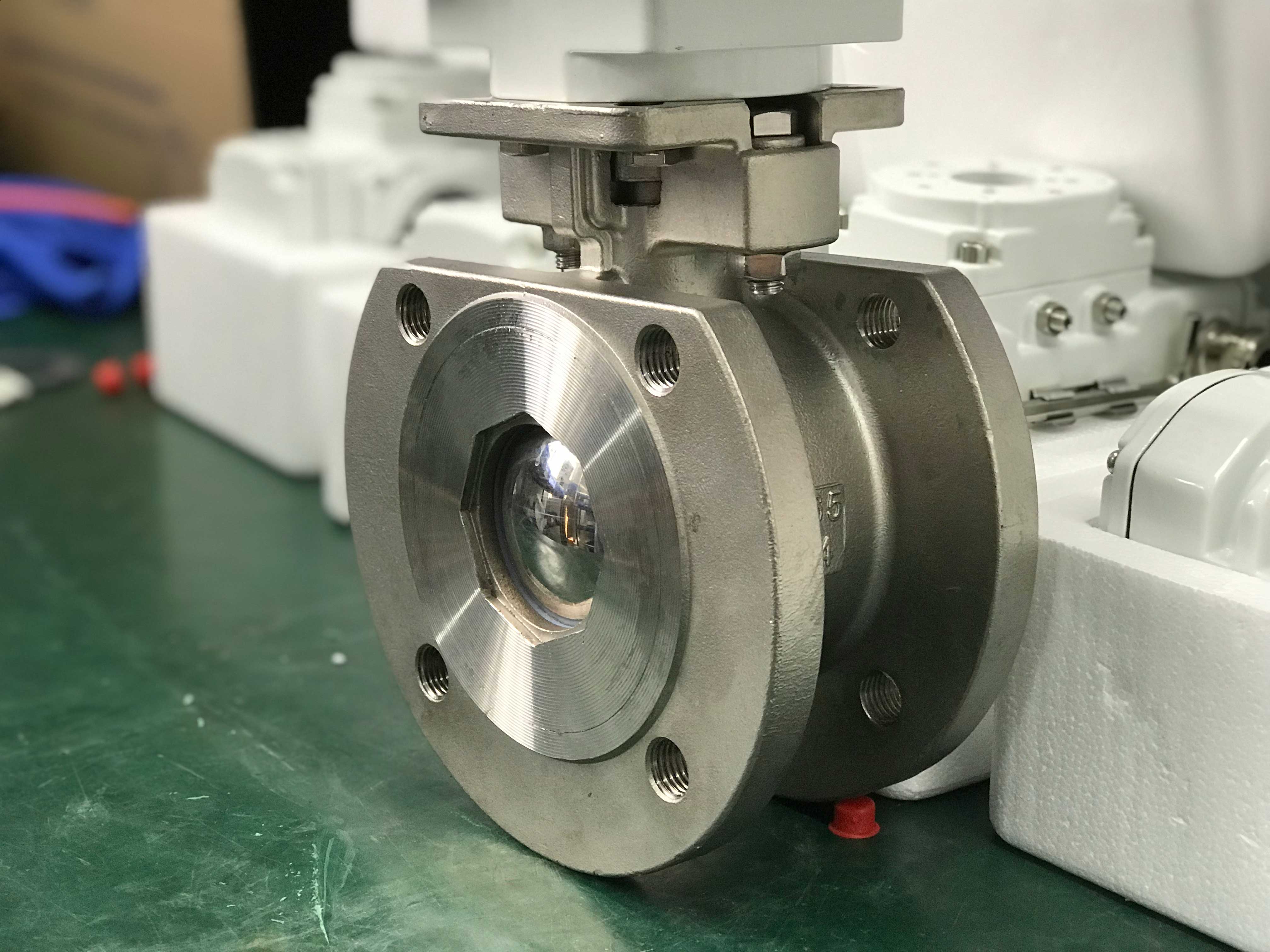

Electric ball valve makes up for the shortage of single and double seat valve used in slurry. The flow path of the ball valve is straight and smooth, and there will be no slurry hanging phenomenon. It changes the fluid flow and accumulates by rotating the sphere, so that the sphere and the valve seat have a shearing effect, and cut off hard objects and sundries. Among them, the V-type ball valve is used for the adjustment of the slurry volume, and the O-type ball valve is used for the on-off control of the slurry flow.

The correct selection of valves and actuators is therefore critical for worker safety, plant safety and paper quality. COVNA adheres to the people-oriented, social sustainable development as the goal, produces automatic valves, and provides industrial automation solutions for many enterprises. Among them, in the paper industry, with many years of project experience, it is the first choice of automatic valve supply for you and your engineers. business.

If you are interested in the above content or are engineers/purchasing managers engaged in the above industries, please contact us for more industrial automation solutions.

Post time: Sep-19-2022