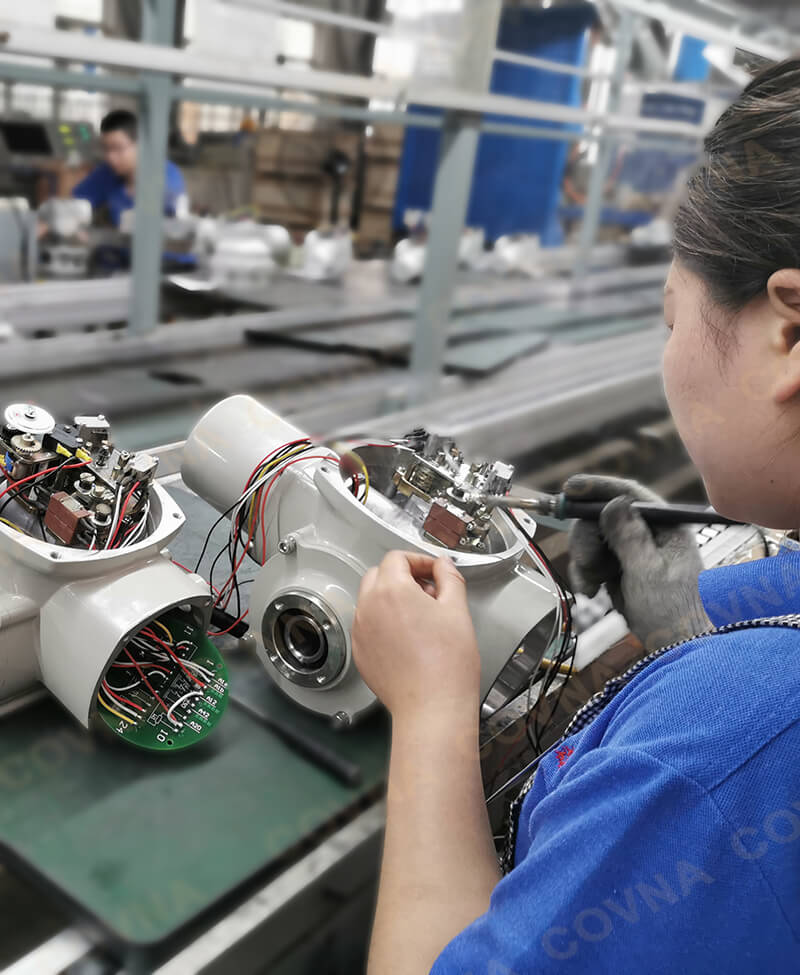

As a valve actuator manufacturer, COVNA provides quater-turn electric actuator and rack and pinion pneumatic actuator for your choice.

Please select the appropriate actuator according to the design of your project. If you have any questions about purchasing, please contact us! We are happy to provide you with quality purchase options.

Both electric and pneumatic actuators are indispensable roles in automation. They all have the same function, and they control fluid flow. But the driving methods and advantages and disadvantages of the two are different. The electric actuator drives the motor by electricity, so as to turn and open the valve. The pneumatic actuator is powered by the air source to open or close the valve.

The Main Advantages of Electric Actuators:

High stability and user-appliable constant thrust. The thrust generated by the maximum actuator can be as high as 225000kgf. Only hydraulic actuators can achieve such a large thrust. The anti-deviation ability of electric actuators is very good. The output thrust or torque is basically constant, which can overcome the unbalanced force of the medium and achieve accurate control of the process parameters, so the control accuracy is better than that of pneumatic actuators high. If it is equipped with a servo amplifier, it can easily realize the exchange of positive and negative effects, and it can also easily set the signal control valve position status (hold/full open/full close). Bit.

However, due to the complicated structure of the electric actuator, it is more prone to failure, and due to its complexity, the technical requirements for on-site maintenance personnel are relatively higher. The motor will generate heat. If the adjustment is too frequent, it will easily cause the motor to overheat and generate thermal protection. At the same time, it will increase the wear on the reduction gear. Secondly, the opening speed of the electric valve is relatively slow.

The actuator and adjustment mechanism of the pneumatic actuator are a unified whole, and its actuators are of the membrane type and the piston type. The piston-type stroke is long, suitable for occasions requiring greater thrust; while the membrane-type stroke is smaller, it can only directly drive the valve stem. Because of its simple structure, large output thrust, stable and reliable action, and safety explosion-proof, pneumatic actuators are widely used in power plants, chemical industries, oil refining and other production processes that require high safety.

The Main Advantages of Pneumatic Actuators:

The price is low, the response is rapid, and the on/off speed is extremely fast. The torque is high, and there are two specifications of single and double action, which can adapt to different industries and meet the needs of different industries. With limit switch and positioner, the signal can be adjusted and connected to the system to achieve remote control. The structure is simple and the failure rate is low.

However, since the pneumatic actuator uses the air source as the power to realize the valve switch, the installation of the pneumatic actuator needs to be matched with a set of air source parts.

Please select the appropriate actuator according to the design of your project. If you have any questions about purchasing, please contact us! We are happy to provide you with quality shopping options.

Post time: Nov-25-2021