Valves have various types of connections like threaded, flanged, welded, tri-clamp, double union and so on. In this article, we will share the details about flanged, threaded and welded.

Flanged Connection Valve —Looking for a flanged valve? Click here to consult us

Flanged valves are easy to install and disassemble, but flanged valves are bulkier and more expensive than threaded valves, so they are suitable for pipe connections of all sizes and pressures. Large size pipeline usually use the flanged connection.

Flanged ball valves and flanged butterfly valves are widely used in wastewater treatment, paper and pulp, shipyard, and other applications which require flanged connection.

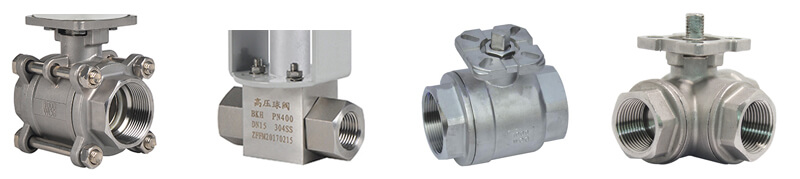

Threaded Connection Valve —Looking for a threaded valve? Click here to consult us

The threaded connection is generally used for pipes less than 50mm. If it is larger than 50mm, we would recommend using flanges and other connection methods.

The threaded connection is divided into G, NPT, BSPP, BSP standards, as well as female and male threads.

The threaded connection is suitable for low-pressure pipelines. Lower price.

Welded Joint Valve —Looking for a welded valve? Click here to consult us

Welding connection refers to welding the valve and the pipe together.

Suitable for pipelines that require zero leakage, such as high temperature and high-pressure pipelines. Welding is divided into socket welding and butt welding.

PS: Welding requires professionals to operate.

All of the threaded, flanged and welded valve with ISO5211 mounting standard for electric actuator and pneumatic actuator.

Don’t figure out which connection should use? Contact us and we will help you to choose the suitable one.

Post time: Jul-28-2021