Globe Valve

For strength testing of globe valves, usually the assembled valve is placed in the test stand, the disc is opened, the media is injected to the specified value, and the valve body and cover are checked for sweating and leakage. One piece may also be subjected to a strength test. Sealing test only for cut-off valves. When the stem of the globe valve is vertical, the disc is open, the medium is introduced from the bottom end of the disc to the specified value, check the packing and gasket;.

If the valve strength and sealing test to do, can first do the strength test, and then reduce pressure to seal test values, check the packing and gasket; then close the disc, open the outlet to check whether the sealing surface leakage.

Gate Valve

Gate valves are tested for the same strength as globe valves.

There are two methods of sealing test for gate Valves:

Then close the gate and take out the gate valve immediately to check whether there is leakage in the seal on both sides of the gate or directly inject the test medium into the plug on the valve cover to the specified value check the seal on both sides of the gate. The above method is called intermediate pressure test. This method is not suitable for sealing test of gate valve with nominal diameter DN32mm or less.

Another method is to open the gate so that the valve test pressure rises to the specified value; then close the gate, open one end of the blind, check whether the sealing surface leakage. Go back again and repeat the test until you pass the test. The sealing test at the packing and Gasket of Gate Valve shall be conducted prior to the sealing test of gate.

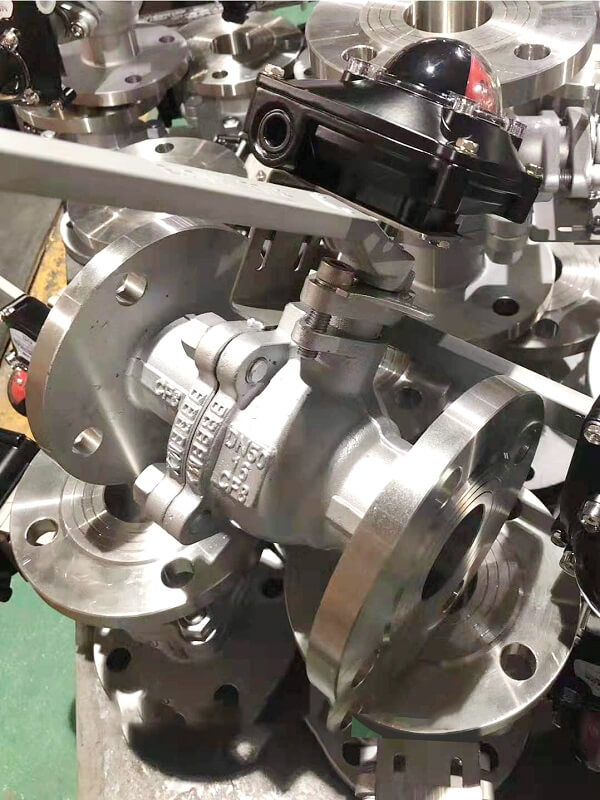

Ball Valve

The strength test of the ball valve shall be carried out in the semi-open state of the ball:

1. Floating ball valve sealing test: the valve is in a half-open state, one end is introduced into the test medium, the other end is closed; the ball is rotated several times, the valve plate is closed state, open the closed end to check, at the same time check the packing and gasket sealing performance, there must be no leakage. The test medium is then introduced from the other end and the test is repeated.

2. Sealing Test of fixed ball valve: Before the test, the ball body is turned several times without load, the valve is in the closed state, the test medium is introduced from one end to the specified value, the sealing performance of the introduction end is checked by pressure gauge, the accuracy of pressure gauge is 0.5 ~ 1, the measuring range is 1.6 times the test pressure. In the specified period of time, no pressure drop phenomenon is qualified, and then from the other end of the introduction of test medium, repeat the above test. Then, the valve is in a half-open state, both ends closed, the cavity fil led with media, under test pressure to check the packing and gasket, no leakage.

3. Three-way ball valve shall be sealed in each position test.

Butterfly Valve

Butterfly valve sealing performance test should be from the medium into the test medium, the butterfly plate should be open, the other end closed, injection pressure to the specified value; check the packing and other seal no leakage, close the butterfly plate, open the other end, check the leakage of butterfly plate seal for qualified. The Butterfly Valve used for regulating flow can not be used for sealing performance test.

Post time: Nov-25-2021