The maintenance principles of valve are as follows:

1. Keep valve exterior and actuated area clean to protect valve paint integrity. The surface of the valve, the trapezoidal threads on the valve stem and the valve stem nut, the sliding part of the valve stem nut and the support, and the gears, worm gears and other parts are easy to deposit a lot of dirt, oil and medium residue, etc. , causes Wear and corrosion to the valve. Therefore, the valve should always be kept clean. The general dust on the valve can be brushed and Compressed air with a brush, or even brushed with a copper wire until the working surface, the mating surface shows a metallic luster and the paint surface shows natural color. The steam trap should be responsible for a person, at least once a shift inspection; regularly open the Wash Valve and steam trap bottom wire plug wash, or regularly remove the wash down, so as not to block the valve dirt.

2. Good lubrication conditions are required to maintain valve lubrication, valve trapezoidal threads, stem nut and bracket sliding positions, bearing positions, gear and worm rotundity positions, and other mating activities, reduce the friction between each other, avoid mutual wear and tear. For no oil Cup or nozzle, easy to damage or loss in operation parts, should be repaired and equipped with complete lubrication system, to verify the oil channel dredge.

Lubrication parts should be regularly refueled according to specific conditions. Frequently opened, high temperature valves are suitable for intervals of a week to a month to refuel; not frequently opened, the temperature of the valve refueling cycle can be longer. Lubricants include organic oil, butter, molybdenum disulfide and graphite. Oil is not suitable for high-temperature valves; butter is not suitable either, as they can be lost through high-temperature melting. High-temperature valves are suitable for adding Molybdenum disulfide and erasing graphite powders. Exposed lubrication parts, such as trapezoidal threads, teeth and other parts if the use of butter and other greases, easily contaminated with dust, and the use of Molybdenum disulfide and graphite powder lubrication is not easy to get dirty and lubrication effect is better than butter, graphite powder is not easy to be directly coated, you can use a little oil or water into paste can be used.

Oil-filling sealing cock valve should be in accordance with the provisions of the time oil, otherwise easy to wear and leak.

3. Keep the two pieces complete and intact. Flange and bracket bolts should be complete, full buckle, not allowed to lose phenomenon. The handwheel on the fastening nut, if loose should tighten in time, so as not to wear out the joint or lose the handwheel. Handwheel is lost, do not allow to use the trap instead of handwheel, should be promptly completed. Packing pressure difference not allowed to skew or no pre-tight gap. Easy to be rain, snow, dust and other pollutants pollution of the environment, the valve stem to install a protective cover. The gauge on the valve should be kept intact and accurate. valve seals, caps, pneumatic accessories should be complete. The heat preservation jacket shall be free from depression and crack.

In addition, the valve is not allowed to knock, support heavy objects or station people, so as not to dirty the valve, or damage the valve. In particular, non-metal net doors and cast iron valves, it is more taboo.

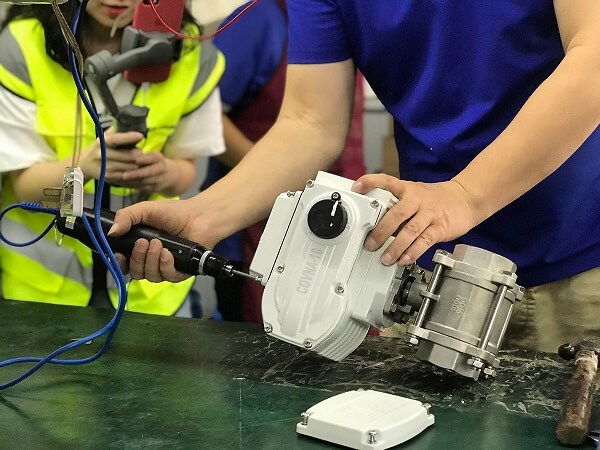

Maintain the daily maintenance of the electric equipment. The maintenance of electrical installations, under normal circumstances not less than once a month. Maintenance content: The appearance should be clean, no dust, the device is not contaminated by soda, oil pollution; sealing Surface, point should be solid, tight. No leakage; lubrication parts should be oiled according to regulations, valve nut should be greased; electrical parts should be intact, no phase fault, automatic switch and thermal relay should not release, indicator light shows correctly.

Post time: Jul-28-2021