Selection And Design Of Valves For HVAC Pipelines:

1. Chilled water unit, cooling water inlet and outlet design butterfly valve.

2. Before the water pump butterfly valve, filter, water pump back check valve, butterfly valve.

3. Differential pressure bypass valve between water collector and water separator.

4. Butterfly valve for inlet and return water pipe of collector and distributor.

5. Horizontal dry pipe butterfly valve.

6. Air handler, strainers, electric two way or three way valves.

7. Fan coil gate valve (or plus electric two-way Valve).

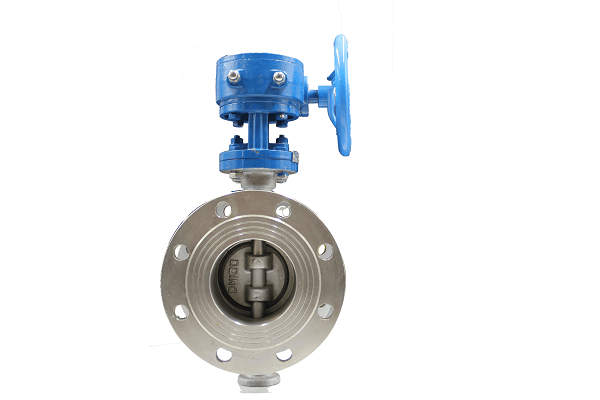

Note: generally when using butterfly valve, the diameter is less than 150 mm when using handle type butterfly valve (D71X, D41X) ; when the diameter is more than 150 mm, using worm wheel drive Type Butterfly Valve (D371x, D341X).

Points To Note When Choosing A HVAC Valve:

1. Pressure reducing valve, balance valve and so on must add by-pass valve.

2. Open and close the best ball valve, gate valve.

3. HVAC pipe to minimize the use of cut-off valve.

4. The resistance calculation of the valve should be paid attention to.

5. Electric valve must be selected.

Selection Principle Of Valve Used In Water Supply Pipeline:

1. Need to adjust the flow, water pressure, the appropriate use of regulating valve, valve.

2. Requests the water flow resistance small spot (like the water pump suction pipe), appropriate use the gate valve.

3. Installation space is small place, appropriate uses butterfly valve, ball valve.

4. The flow of water to the two-way flow of the pipe, shall not use the cut-off Valve.

5. The larger diameter of the pump, the outlet pipe should be used on the multi-function valve.

Check Valve Setting Requirements:

1. Lead into the tube.

2. On the inlet pipe of the closed water heater or water using equipment.

3. Pump the water out of the pipe.

4. The inlet and outlet pipes of the cisterns, water towers, and upland cisterns share a single pipe.

Note: No check valve is required for pipe sections with piping backflow preventer.

Valve Type Selection For Check Valve:

Check valve shall be based on the installation site, valve before the water pressure, closed after the performance requirements and closed when the water hammer caused by factors such as the size, should meet the following 4 requirements:

1. The water pressure before the valve small part, should choose swing check valve, ball check valve and shuttle check valve.

2. Closed after the sealing performance requirements of the tight parts, the appropriate selection of the closed spring check valve.

3. Request to weaken the position of the water hammer closed, should choose to quickly close the noise check valve or with a damping device slow closed check valve.

4. Check valve or spool, should be able to gravity or spring under the action of self-closing.

Exhaust Devices Shall Be Provided In The Following Parts Of The Water Supply Pipeline:

1. Intermittent cycle of water supply network, its pipe network and the highest point should be equipped with automatic exhaust valve.

2. The pipe section with obvious undulation and accumulation of air in the water supply network has been equipped with automatic exhaust valve or manual valve at the peak point of the section.

3. Air pressure water supply device, when the use of automatic air supply type air pressure water tank, the highest point of the water distribution network should be set up automatic exhaust valve.

Post time: Jul-28-2021