Feed production is vital to the livestock and aquaculture industries because of its significant impact on animal growth, health, and productivity. Here are some important reasons why feed production is crucial.

Providing Adequate Nutrition

Feed is the main source of nutrients for animals. Proper feed production can ensure that animals get the necessary nutrients to grow, maintain good health, and produce high-quality products.

Reducing Farming Costs

High-quality feed can lower animal production costs. Careful planning and management of feed production can reduce waste and losses, thereby lowering farming and breeding costs.

Improving Food Quality

Suitable feed can improve the quality and taste of the food produced. For example, by adding specific ingredients to the feed, more fat and protein can be produced, improving the quality of meat and dairy products.

Why Valves Are Important For Feed Production

● Control Of Material Flow

Valves can control the flow rate and speed of materials, ensuring that materials are appropriately processed during production.

● Adjustment Of Process Parameters

Valves can adjust process parameters such as temperature, pressure, flow rate, processing time, etc. By adjusting these parameters, the properties and quality of feed can be changed.

● Preventing Contamination And Cross-contamination

Valves can cut off connections between different production lines, preventing cross-contamination between feeds and ensuring their hygiene and safety.

● Automation Control

Valves can be integrated with control systems to achieve automation control. Through automatic control, production efficiency and quality can be improved while reducing manual intervention and operation time.

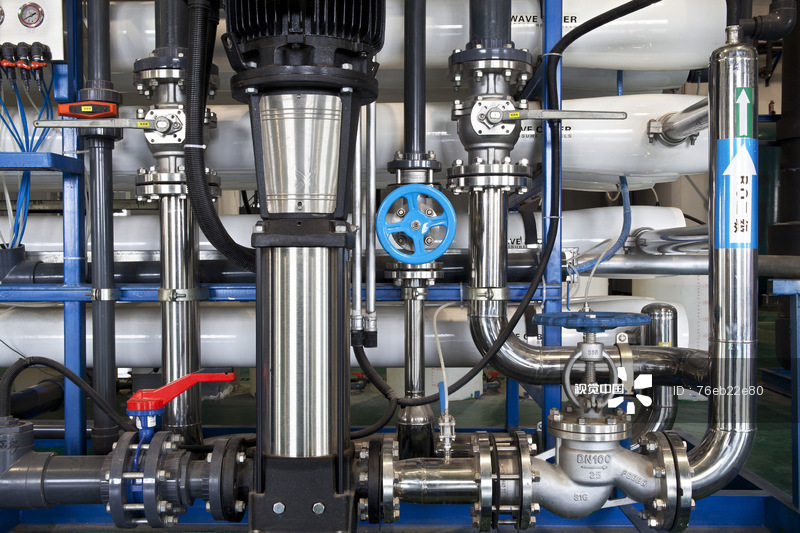

The Role Of Valves In Different Processes Of Feed Production And Processing

● Storage And Batching

In the process of feed production, raw materials usually need to be stored and batched first. Valves are mainly used to control the input, transportation, and mixing of raw materials, ensuring that raw materials are mixed in the correct proportion and order. For example, valves need to be installed at locations such as silo doors, discharge ports, conveying pipelines, and mixers to control the flow rate and flow velocity of raw materials.

● Crushing And Mixing

After storage and batching are completed, raw materials need to be crushed and mixed. Valves are mainly used to control the time, speed, and intensity of crushing and mixing to achieve the desired effect. For example, crushing machines and mixers need to have valves installed to control the input and processing areas.

● Processing And Granulating

After crushing and mixing are completed, raw materials need to be processed and granulated. Valves are mainly used to control the process parameters such as temperature, pressure, and flow rate during processing and granulating, to obtain the desired finished product. For example, processing equipment and pelletizers need to have valves installed to control the input and processing areas.

● Packaging And Storage

After processing and granulating are completed, finished products need to be packaged and stored. Valves are mainly used to control the transportation and packaging of finished products to ensure their hygiene and safety. For example, packaging machines and conveying equipment need to have valves installed to control the transportation and packaging of finished products. In addition, valves are also needed to control finished products during storage and transportation to ensure their quality and safety.

Valve Selection In Feed Production

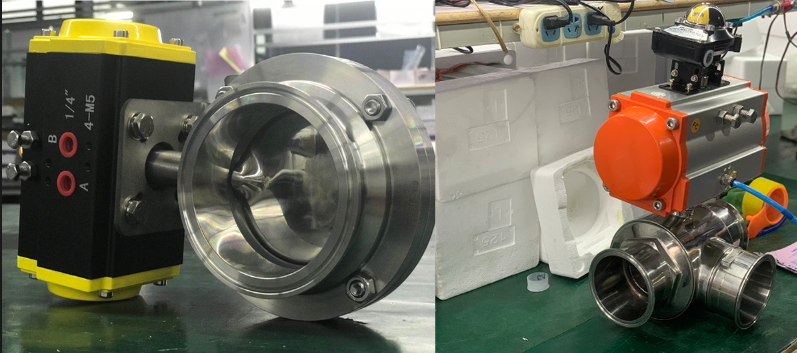

In feed production, it is necessary to control the temperature of the heater. At this point, pneumatic control valves can be installed to regulate the heat output of the heater and adjust its temperature. Similarly, in the mixing and pressing stage, pneumatic control valves are needed to control the flow and pressure of the mixer and press, ensuring the consistency and quality stability of feed particle size, shape, and hardness.

In the raw material processing and packaging stage, pneumatic sanitary butterfly valves or pneumatic sanitary ball valves are required to control the flow and prevent impurities and bacterial contamination of raw materials and products, ensuring their hygiene and safety.

The use of pneumatic actuators in feed production can increase productivity, reduce costs, and improve product quality and safety.

Reduce costs – The use of pneumatic actuators in feed production equipment can reduce labor costs by reducing operator intervention and the need for maintenance personnel.

Improved efficiency – Pneumatic actuators offer fast response times and high control accuracy. This enables feed production equipment to achieve faster production speeds and higher production efficiencies.

Improved production quality and safety – Pneumatic actuators provide precise control of feed production equipment operating parameters, resulting in improved product consistency and productivity, as well as fewer accidents due to misuse.

In the mixing and pressing stage, sanitary valves are needed to control the flow of different raw materials in the feed mixer, ensuring the accuracy and uniformity of mixing ratio, as well as controlling the feeding and discharging of the press, ensuring the consistency and quality stability of feed particle size, shape, and hardness.

Sanitary valves are made of hygienic materials, corrosion-resistant, rust-proof, and pollution-resistant. They prevent cross-contamination caused by bacteria and other pollutants, ensuring product safety and hygiene.

Maintenance And Upkeep Of Valves In Feed Production

● Regular Cleaning And Disinfection

Sanitary valves should be regularly cleaned and disinfected to avoid the accumulation of bacteria and other contaminants that can lead to cross-contamination. Use appropriate cleaning and disinfecting agents and replace vulnerable components such as gaskets and O-rings regularly.

● Inspection And Replacement Of Vulnerable Components

Vulnerable components such as gaskets and O-rings in sanitary valves are prone to wear and aging. They should be inspected and replaced regularly to ensure proper valve function and sealing performance.

● Regular Inspection And Maintenance

Regularly inspect the connection components, supports, bolts, and nuts of sanitary valves and piping systems to ensure equipment safety and stable operation.

Sanitary valves play a crucial role in feed production, especially in achieving sanitary production, improving production efficiency, protecting equipment, and ensuring product quality, among other functions. Therefore, choosing and maintaining sanitary valves in feed production is vital.

If you are looking for a reliable pneumatic valve to improve the efficiency and quality of feed production, we strongly recommend purchasing COVNA valves. COVNA valves have been widely used in the feed industry and have received positive feedback from users. By purchasing COVNA valves, you will also benefit from our high-quality service and technical support. Contact us now!

Post time: Mar-23-2023