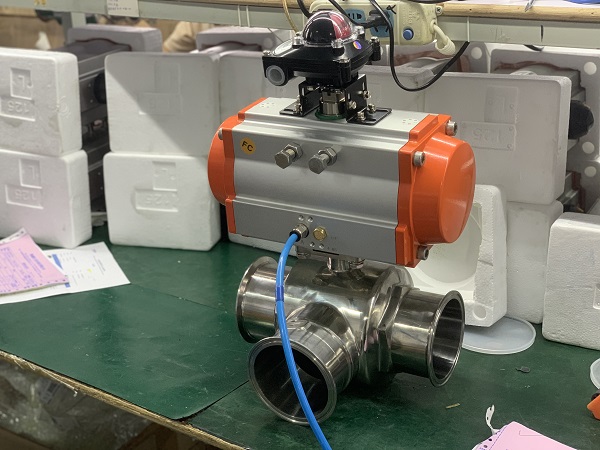

A three-way ball valve is a relatively new type of ball valve. It has some unique advantages of its own structure. For example, the switch has no friction, the seal is not easy to wear, and the opening and closing torque is small. This can reduce the specifications of the actuators equipped. With electric actuators or pneumatic actuators, the media can be adjusted and cut off remotely. It is widely used in petroleum, chemical, urban water supply and drainage applications. Three-way ball valves have T-type and L-type. The T-shape can make three orthogonal pipes communicate with each other and cut off the third channel, so as to shunt and merge. L three-way ball valve type can only connect two mutually orthogonal pipes, and cannot keep the third pipe connected to each other at the same time.

Three-Way Ball Valve Structure:

1. The three-way ball valve adopts an integrated structure in structure, the sealing type of the four-sided valve seat, less flange connection, high reliability, and the design achieves lightweight.2. The three-way ball valve includes a valve body, a valve core and a valve stem. One end of the valve stem of the product is linked with the valve core, and the other end passes through the valve body and is linked with an external drive mechanism.3. The spool of the three-way ball valve is provided with an L-shaped fourth flow channel. The valve body of the product is provided with a fifth flow channel through the spool to connect or disconnect the first flow channel and the third flow channel

Installation Of Three-Way Ball Valve:

1. The three-way ball valve should have a position where the valve handle rotates.2. The three-way ball valve cannot be used as a throttle, it can only divert or control the medium3. The ball valve with an actuator should be installed vertically

Post time: Nov-25-2021