Sa kaharian ng mga kagamitan sa pang -industriya, ang kahalagahan ng mga electric valves ay hindi ma -overstated. Sila ang mga unsung bayani, tinitiyak ang makinis at mahusay na daloy ng mga likido sa maraming mga aplikasyon. Ngunit pagdating sa pagpili ng tamang tagagawa ng electric valve, isang pangalan ang nakatayo: covna.

Ang Covna ay naging isang trailblazer sa industriya nang maraming taon. Ang aming paglalakbay ay nagsimula sa isang simple ngunit malakas na pangitain: upang magbigay ng mga nangungunang mga solusyon sa balbula na nag-aasawa sa pagiging maaasahan. Ang pangitain na ito ay nagtulak sa amin sa unahan ng pandaigdigang merkado ng balbula.

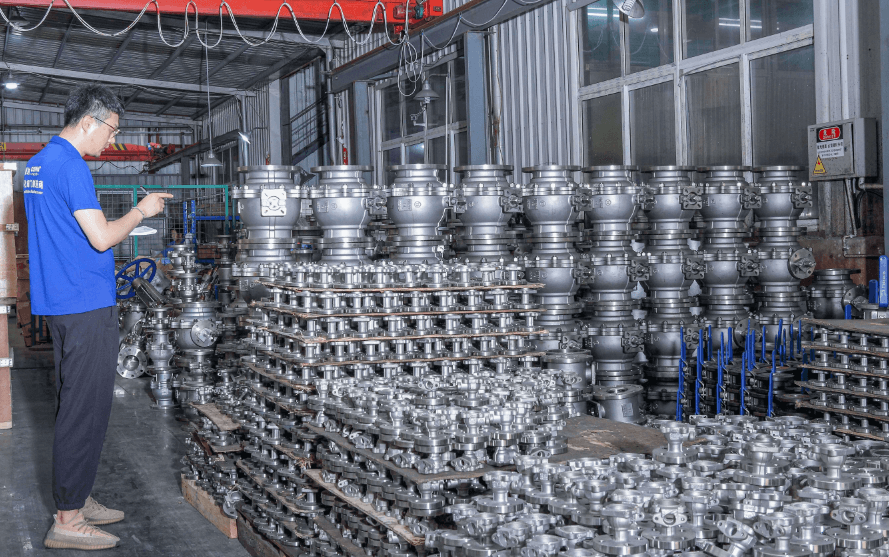

Ano ang nagtatakda ng covna? Ito ang aming walang tigil na pangako sa kalidad. Ang bawat balbula na gumulong sa aming mga pasilidad ng produksyon ng state-of-the-art ay sumasailalim sa mahigpit na pagsubok. Naiintindihan namin na sa mga industriya tulad ng paggamot sa tubig, petrolyo, at henerasyon ng kuryente, kahit na ang bahagyang madepektong paggawa ay maaaring humantong sa magastos na pagkagambala. Iyon ang dahilan kung bakit ang aming mga balbula ay itinayo hanggang sa huli, na may pinakamalawak na mga kondisyon at gumaganap nang walang kamali -mali taon -taon.

Ang aming saklaw ng produkto ay isa pang balahibo sa aming takip. Mula sa mga solenoid valves na nag -aalok ng mabilis na mga oras ng pagtugon sa mga pneumatic valves na nagbibigay ng tumpak na kontrol, at siyempre, ang aming mga punong -puri na mga balbula ng electric na pinagsama ang kapangyarihan at kawastuhan, mayroon kaming solusyon para sa bawat pangangailangan. At hindi lamang ito tungkol sa mga karaniwang handog; Ang aming koponan ng mga eksperto ay patuloy na nagbabantay para sa mga paraan upang makabago. Ito ay humantong sa pag -unlad ng mga espesyal na balbula na umaangkop sa mga industriya ng angkop na lugar, paglutas ng mga kumplikadong problema na nahihiya ng iba.

2. Isang magkakaibang hanay ng mga de-kalidad na balbula

Sa Covna, ipinagmamalaki namin ang aming sarili sa aming malawak na saklaw ng produkto, ang bawat balbula ay dinisenyo at nilikha ng katumpakan.

2.1 Solenoid Valves: Katumpakan sa bawat switch

Ang aming mga solenoid valves ay isang kamangha -manghang engineering. Ginagamit nila ang puwersa ng electromagnetic upang makontrol ang daloy ng mga likido na may katumpakan ng pinpoint. Sa mga application tulad ng mga awtomatikong sistema ng dosing ng kemikal o mga halaman ng paggamot ng katumpakan ng tubig, kung saan kahit na ang pinakamaliit o sa ilalim ng dosis ay maaaring magkaroon ng makabuluhang mga kahihinatnan, ang aming mga solenoid valves ay lumiwanag. Sa mabilis na oras ng pagtugon at maaasahang operasyon, tinitiyak nila na ang tamang dami ng likido ay naihatid sa eksaktong sandali na kinakailangan.

2.2 Pneumatic Valves: Powering Automation

Ang mga pneumatic valves ay bumubuo ng gulugod ng maraming mga awtomatikong proseso ng pang -industriya. Ang mga balbula na ito ay gumagamit ng naka -compress na hangin upang mapatakbo, na nagbibigay ng isang malakas at mahusay na paraan ng pagkontrol ng daloy ng likido. Sa malakihang mga halaman ng pagmamanupaktura, kung saan ang bilis at pagiging maaasahan ay ang kakanyahan, ang aming mga pneumatic valves ay nagpapanatili ng mga linya ng produksyon na humuhuni. Ang kanilang tibay at kakayahang makatiis ng malupit na mga kondisyon ng pagpapatakbo ay ginagawang paborito sa kanila sa mga industriya tulad ng automotive manufacturing at mabibigat na makinarya.

2.3 Electric Valves: Ang core ng aming kadalubhasaan

Tulad ng iminumungkahi ng pangalan, ang mga electric valves ay kung saan ang aming kadalubhasaan ay tunay na dumating sa unahan. Pinagsasama ng mga balbula na ito ang mga advanced na teknolohiya ng motor sa mga intelihenteng sistema ng kontrol. Kung ito ay nasa isang sistema ng HVAC ng mataas na pagtaas ng gusali, kung saan ang tumpak na regulasyon ng temperatura ay mahalaga para sa kaginhawaan ng sumasakop, o sa isang sistema ng paglamig ng planta ng kuryente, kung saan ang napakalaking dami ng tubig ay kailangang kontrolin, ang aming mga electric valves ay naghahatid. Nag -aalok sila ng walang tahi na pagsasama sa mga modernong sistema ng automation, na nagpapahintulot sa remote na pagsubaybay at kontrol.

2.4 at marami pa: Gate, Globe, Butterfly, Control, Safety Valves & Specialty

Higit pa sa mga pangunahing handog, ang lineup ng produkto ng Covna ay may kasamang malawak na hanay ng mga balbula upang matugunan ang bawat hindi maiisip na pangangailangan. Ang mga balbula ng gate, na kilala para sa kanilang mahusay na mga kakayahan sa pag-shut-off, ay mainam para sa mga aplikasyon kung saan kinakailangan ang isang masikip na selyo, tulad ng sa mga pipeline ng supply ng tubig. Ang mga balbula ng Globe, kasama ang kanilang tumpak na kontrol ng daloy, ay hanapin ang kanilang lugar sa mga halaman sa pagproseso ng kemikal. Ang mga balbula ng butterfly, kasama ang kanilang magaan na disenyo at mabilis na operasyon, ay perpekto para sa mga malalaking diameter na mga piping system sa mga industriya tulad ng paggamot sa tubig at HVAC. Ang mga control valves, na idinisenyo upang ayusin ang daloy batay sa mga tiyak na mga parameter, matiyak ang pinakamainam na pagganap sa mga kumplikadong proseso ng pang -industriya. Ang mga balbula sa kaligtasan, isang kritikal na sangkap sa anumang pressurized system, ay nagbibigay ng isang mekanismo na ligtas na ligtas upang maiwasan ang over-pressurization at mga potensyal na sakuna. At ang aming mga espesyal na balbula, na binuo bilang tugon sa mga natatanging mga hamon sa industriya, ay nag -aalok ng mga solusyon sa bespoke na nagtatakda sa amin mula sa kumpetisyon.

3. Hindi magkatugma na pandaigdigang aplikasyon

Ang mga balbula ng Covna ay gumawa ng kanilang marka sa isang malawak na spectrum ng mga industriya, na tunay na nagiging isang pandaigdigang puwersa. Sa paggamot ng tubig at wastewater, ang aming mga balbula ay ang mga tagapag -alaga ng malinis na tubig. Kinokontrol nila ang daloy ng hilaw na paggamit ng tubig, tinitiyak na ang mga halaman ng paggamot ay nagpapatakbo sa pinakamainam na kapasidad. Sa proseso ng paglilinis, ang tumpak na mga control valves ay nagpapanatili ng tamang dosing ng kemikal, habang ang matibay na mga balbula ng gate at mga balbula ng butterfly ay namamahala ng daloy sa mga network ng pamamahagi, na nagbibigay ng malinis na tubig sa mga komunidad.

Ang industriya ng automation ay nagtatagumpay sa pagiging maaasahan ng aming solenoid at electric valves. Ang mga balbula na ito ay nagbibigay-daan sa walang tahi na operasyon sa mga proseso ng pagmamanupaktura ng robotic, kung saan mahalaga ang mga split-second na desisyon. Kinokontrol nila ang mga sistema ng pneumatic at haydroliko na nagbibigay kapangyarihan sa mga robotic arm, tinitiyak na ang mga linya ng produksyon ay nagtitipon ng mga produkto na may katumpakan at bilis.

Sa mga sektor ng petrolyo at kemikal, ang aming mga balbula ay nahaharap sa ilan sa mga pinakapangit na kondisyon. Ang mga mataas na temperatura, kinakaing unti -unting kemikal, at matinding panggigipit ay pamantayan. Ngunit ang mga balbula ng covna, na nilikha mula sa mga dalubhasang haluang metal at dinisenyo na may mga advanced na mekanismo ng sealing, tumayo sa pagsubok. Mula sa mga platform ng pagbabarena sa malayo sa pampang kung saan pinamamahalaan ng mga control valves ang daloy ng langis ng krudo hanggang sa mga halaman ng kemikal kung saan pinipigilan ng mga balbula sa kaligtasan ang sakuna na over-pressurization, tinitiyak ng aming mga produkto ang maayos at ligtas na operasyon.

Ang industriya ng kuryente, maging thermal, hydro, o nuklear, ay umaasa sa aming mga balbula para sa mga kritikal na pag -andar. Sa mga thermal power plant, kontrolin ng mga electric valves ang daloy ng singaw at paglamig ng tubig, na -optimize ang kahusayan ng henerasyon ng kuryente. Sa mga pasilidad ng nuklear, ang aming mga espesyal na inhinyero na mga balbula ay sumunod sa mahigpit na pamantayan sa kaligtasan, na pag -iingat laban sa mga potensyal na meltdowns. At sa nababagong sektor ng enerhiya, tulad ng mga solar thermal halaman, pinamamahalaan ng aming mga balbula ang mga fluid ng paglipat ng init, tinitiyak na ang pag -convert ng enerhiya ay na -maximize.

Ang mga operasyon ng metalurhiya at pagmimina ay pantay na nakasalalay sa covna. Sa mga smelting furnaces, ang mga high-temperatura na lumalaban sa mga balbula ay nag-regulate ng daloy ng mga tinunaw na metal, habang sa pagmimina, matibay na mga balbula ng gate at globo ay humahawak ng mga nakasasakit na slurries, na kumukuha ng mahalagang mga mapagkukunan nang walang mga breakdown. Ang mga industriya ng paggawa at parmasyutiko ay nakikinabang mula sa aming kalinisan at tumpak na mga balbula. Sa mga mill mills, kinokontrol ng mga balbula ng butterfly ang daloy ng mga slurries ng pulp, at sa mga lab na parmasyutiko, tinitiyak ng mga solenoid valves ang tumpak na dosis ng mga sensitibong gamot, na pinapanatili ang integridad ng mga produkto ng pagtatapos.

4.1 Cutting-Edge R&D para sa Mga Solusyon na Handa sa Hinaharap

Sa Covna, naiintindihan namin na ang mundo ng mga proseso ng industriya ay patuloy na umuusbong. Iyon ang dahilan kung bakit kami ay namuhunan nang labis sa pananaliksik at pag -unlad. Ang aming koponan ng mga maningning na inhinyero at technician ay patuloy na nag -scan ng abot -tanaw para sa mga umuusbong na mga uso at teknolohiya. Kung ito ay ang pagsasama ng artipisyal na katalinuhan para sa mahuhulaan na pagpapanatili ng mga balbula o ang paggamit ng mga advanced na materyales upang mapahusay ang tibay sa matinding mga kondisyon, nasa unahan tayo.

Nakikipagtulungan kami sa mga nangungunang mga institusyon ng pananaliksik at mga eksperto sa industriya upang matiyak na ang aming mga balbula ay hindi lamang nakakatugon sa mga pangangailangan ngayon ngunit handa din sa hinaharap. Ang diskarte sa pag-iisip ng pasulong na ito ay humantong sa pag-unlad ng mga makabagong solusyon tulad ng paglilinis ng mga balbula para sa mga aplikasyon kung saan ang mga impurities ng likido ay maaaring maging sanhi ng pag-clog, at mga balbula na mahusay sa enerhiya na nag-aambag sa pangkalahatang mga layunin ng pagpapanatili sa mga pang-industriya na operasyon.

4.2 mahigpit na kontrol ng kalidad sa bawat yugto

Ang kalidad ay hindi lamang isang buzzword sa Covna; Ito ang pundasyon ng aming operasyon. Mula sa sandaling dumating ang mga hilaw na materyales sa aming mga pasilidad, napapailalim sila sa mahigpit na inspeksyon. Pinagmulan namin ang aming mga materyales mula sa mga pinagkakatiwalaang mga supplier, at ang bawat batch ay nasubok gamit ang state-of-the-art na kagamitan upang matiyak na nakakatugon ito sa aming mga pamantayan.

Sa panahon ng proseso ng pagmamanupaktura, ang bawat balbula ay sumasailalim sa maraming mga tseke ng kalidad. Ang aming mga bihasang manggagawa ay maingat na nagtitipon ng bawat sangkap, at pagkatapos ng bawat yugto ng paggawa, mula sa machining hanggang sa pagpupulong, ang mga produkto ay sinuri para sa katumpakan at pagganap. Bago iniwan ng isang balbula ang aming pabrika, dapat itong pumasa sa isang baterya ng mga pagsubok, kabilang ang mga pagsubok sa presyon, mga pagsubok sa pagtagas, at mga pagsusuri sa pagbabata, pag-simulate ng mga kondisyon sa pagpapatakbo ng real-world. Tinitiyak nito na kapag nag -install ang aming mga customer ng isang balbula ng covna, maaari silang magkaroon ng kumpletong tiwala sa pagiging maaasahan nito.

4.3 Serbisyo ng Customer-Centric: Ang iyong kasiyahan, ang aming prayoridad

Naniniwala kami na ang aming relasyon sa aming mga customer ay hindi magtatapos kapag bumili sila ng isang balbula; simula pa lang. Ang aming dedikadong koponan ng serbisyo sa customer ay magagamit sa paligid ng orasan upang makatulong sa anumang mga query o alalahanin. Bago ang isang pagbili, ang aming mga eksperto ay nagtatrabaho nang malapit sa mga customer upang maunawaan ang kanilang mga tiyak na kinakailangan. Kung ito ay tumutulong sa kanila na pumili ng tamang balbula para sa isang partikular na aplikasyon o pagbibigay ng mga pasadyang solusyon para sa mga natatanging hamon, naroroon kami sa bawat hakbang.

Sa panahon ng pag-install, nag-aalok kami ng komprehensibong suporta, kabilang ang detalyadong mga gabay sa pag-install at, kung kinakailangan, tulong sa site. At pagkatapos ng pagbebenta, ang aming koponan ng serbisyo pagkatapos ng benta ay palaging nasa standby. Kung ang isang customer ay nahaharap sa anumang mga isyu, agad kaming tumugon, na nagbibigay ng pag -aayos at, kung kinakailangan, mga kapalit na bahagi o yunit. Ang aming layunin ay upang matiyak na ang mga operasyon ng aming mga customer ay tumatakbo nang maayos, na binabawasan ang downtime at pag -maximize ang pagiging produktibo.

5. Ang kalamangan ng covna noong 2024 at higit pa

Sa unahan, ang Covna ay naghanda upang ipagpatuloy ang paitaas na tilapon. Sa mga tuntunin ng makabagong teknolohiya, namumuhunan kami sa pananaliksik at pag-unlad ng mga susunod na henerasyon na mga balbula. Kasama dito ang pagsasama ng artipisyal na katalinuhan para sa mahuhulaan na pagpapanatili, na nagpapahintulot sa aming mga customer na maasahan at matugunan ang mga potensyal na isyu sa balbula bago nila guluhin ang mga operasyon. Sinasaliksik din namin ang paggamit ng mga advanced na materyales, tulad ng mga nanocomposites, na nag -aalok ng pinahusay na lakas at paglaban ng kaagnasan, na karagdagang pagpapalawak ng habang -buhay ng ating mga balbula kahit na ang pinakamasamang kapaligiran.

Sa harap ng pagpapalawak ng merkado, mayroon kaming mga tanawin na nakatakda sa mga umuusbong na ekonomiya. Ang mga rehiyon tulad ng Timog Silangang Asya, Africa, at Timog Amerika ay nakasaksi sa mabilis na industriyalisasyon, at ang demand para sa maaasahang mga solusyon sa balbula ay skyrocketing. Nagtatatag kami ng mga lokal na pakikipagsosyo at mga network ng pamamahagi upang matiyak na ang aming mga produkto ay madaling magagamit at suportado sa mga rehiyon na ito. Hindi lamang ito makakatulong sa amin na mag -tap sa mga bagong base ng customer ngunit pinapayagan din kaming mag -ambag sa paglaki ng mga industriya sa mga lugar na ito.

Ang pagpapanatili ay nasa gitna ng ating mga plano sa hinaharap. Habang lumilipat ang mundo patungo sa isang greener sa hinaharap, ang covna ay nakatuon upang mabawasan ang bakas ng carbon nito. Ang aming mga proseso ng pagmamanupaktura ay na -optimize upang mabawasan ang pagkonsumo ng enerhiya at henerasyon ng basura. Bilang karagdagan, kami ay bumubuo ng mga balbula na mas mahusay sa enerhiya, na tumutulong sa aming mga customer sa mga industriya tulad ng henerasyon ng kuryente at paggamot ng tubig upang mapatakbo nang higit pa. Sinasaliksik din namin ang mga inisyatibo sa pag -recycle para sa aming mga produkto sa pagtatapos ng kanilang siklo sa buhay, tinitiyak na nag -aambag tayo sa isang pabilog na ekonomiya.

Sa konklusyon, habang tumatakbo pa tayo sa 2024 at higit pa, ang Covna ay nananatiling nakatuon sa pagiging pandaigdigang pinuno sa mga propesyonal na balbula. Ang aming pokus sa pagbabago, kalidad, kasiyahan ng customer, at pagpapanatili ay magpapatuloy na magmaneho sa amin pasulong, tinitiyak na ang mga industriya sa buong mundo ay maaaring umasa sa aming mga balbula sa darating na mga dekada. Kung pinapagana nito ang susunod na henerasyon ng mga nababago na halaman ng enerhiya, pag -iingat sa mga pasilidad ng paggamot sa kritikal na tubig, o pagpapagana ng walang tahi na automation sa pagmamanupaktura, narito ang CovNA upang maganap ito. Piliin ang Covna, at pumili ng isang kasosyo na nakatuon sa iyong tagumpay at hinaharap ng pag -unlad ng industriya.

6. Sumali sa mga kamay kay Covna ngayon!\

Huwag palampasin ang pagkakataon na makipagsosyo sa Covna, ang 2024 pandaigdigang pinuno sa mga propesyonal na balbula. Kung nangangailangan ka ng mga nangungunang kalidad ng mga balbula para sa isang bagong proyekto o naghahanap upang i-upgrade ang iyong umiiral na mga sistema, handa na ang aming koponan na tumulong. Sa aming malawak na saklaw ng produkto, hindi magkatugma na kalidad, at nakatuon na serbisyo, ginagarantiyahan namin ang kasiyahan. Abutin ang sa amin ngayon at magtayo tayo ng isang maunlad na hinaharap na magkasama. Ang iyong tagumpay ay ang aming misyon, at sa mga balbula ng covna, pinipili mo ang pagiging maaasahan, pagbabago, at isang kasosyo para sa mahabang paghatak.

Oras ng Mag-post: Dis-27-2024